THE PRECISION TECHNOLOGY BEHIND BEVEL PLASMA CUTTING MACHINE

In order to guarantee quality control, it is essential to parallel-offset the cutting contour or laterally offset the machine when making multiple bevel cuts. When considering the need to match drive speed and cutting amperage to the specific bevel being cut, it becomes evident that any error made by the machine or operator can result in a costly mistake.

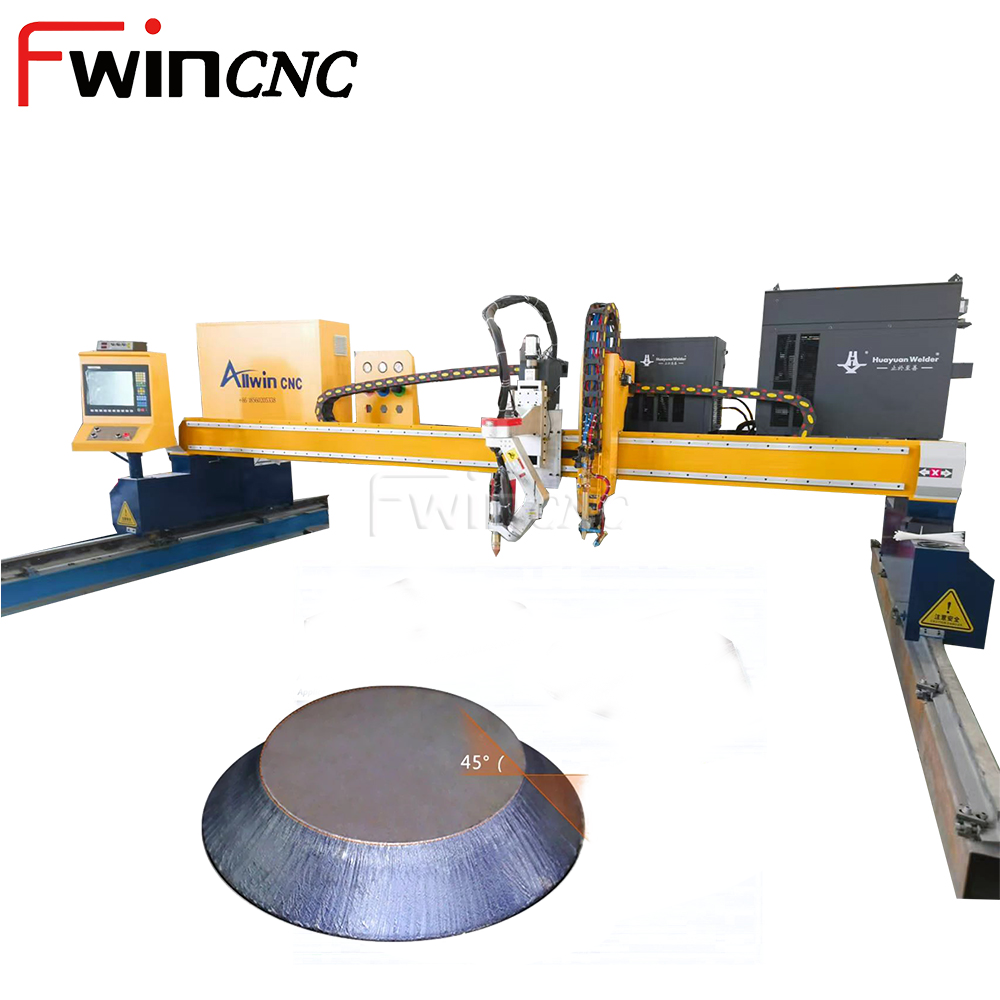

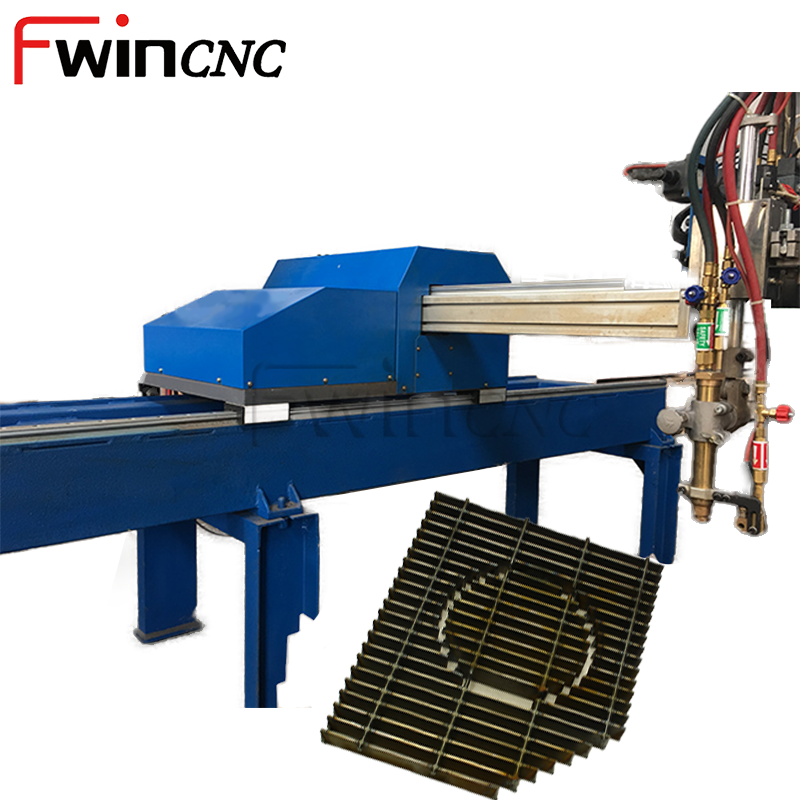

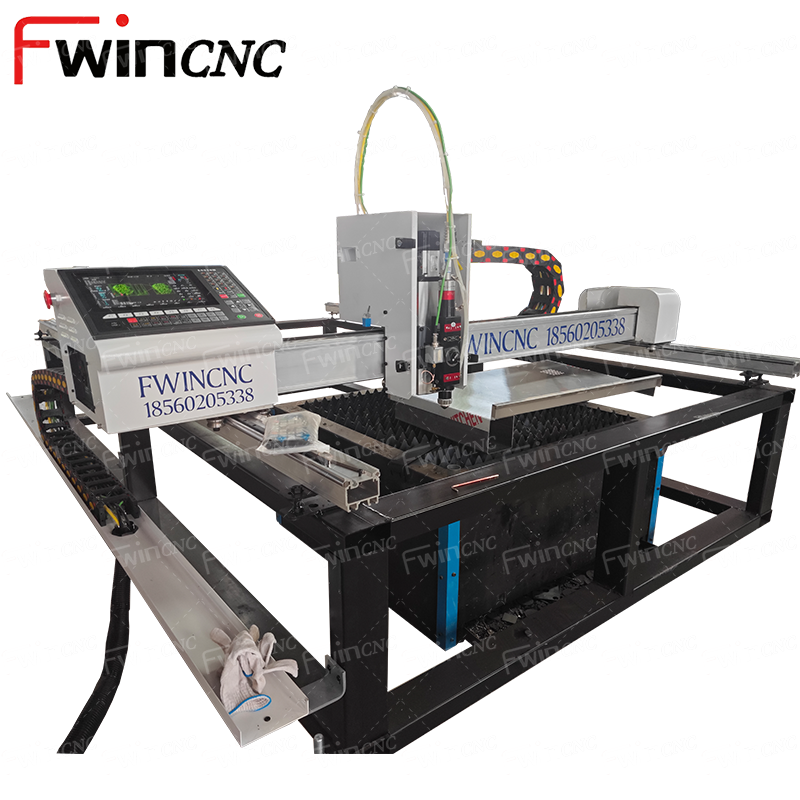

Our FWIN machines 5 Aixs CNC Metal Bevel Plasma Cutting Machineare equipped with cutting-edge technology that minimizes the chances of expensive errors. We have a deep understanding of the machinery and have tailored our solutions to simplify the plasma cutting process by incorporating intricate features. FWIN excels in bevel plasma cutting machine, handing various complexities such as multiple bevel in repeated cuts, adjusting the cutting contour for parallelism, lateral offsetting, geometric start cuts, and dine-tuning technology parameters like drive, speed, and cutting amperage to match the bevel. Our 5 Aixs CNC metal bevel plasma cutting machine are designed to address these precise requirements in plasma bevel cutting.