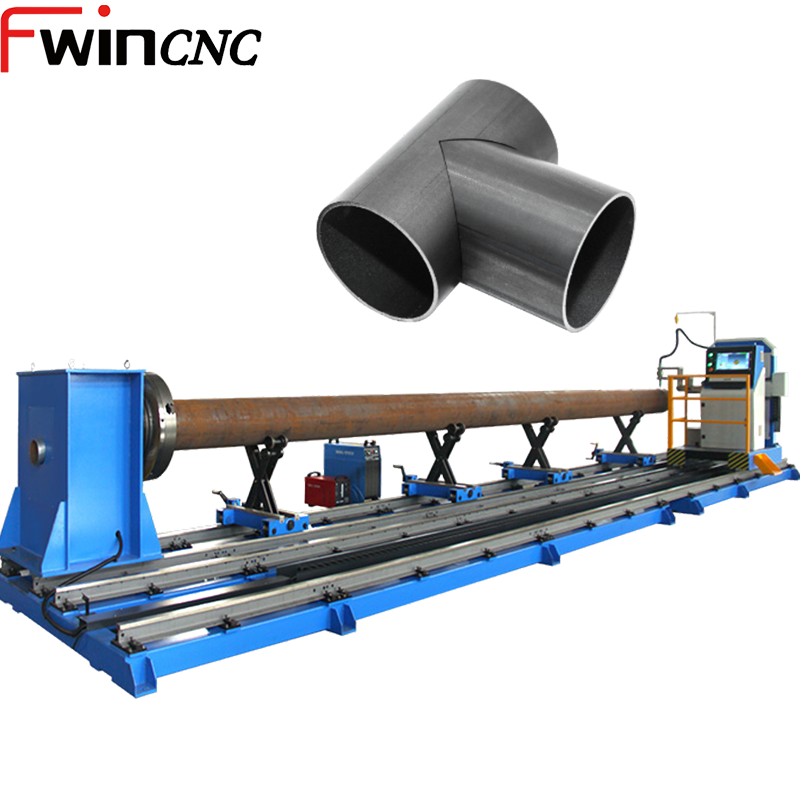

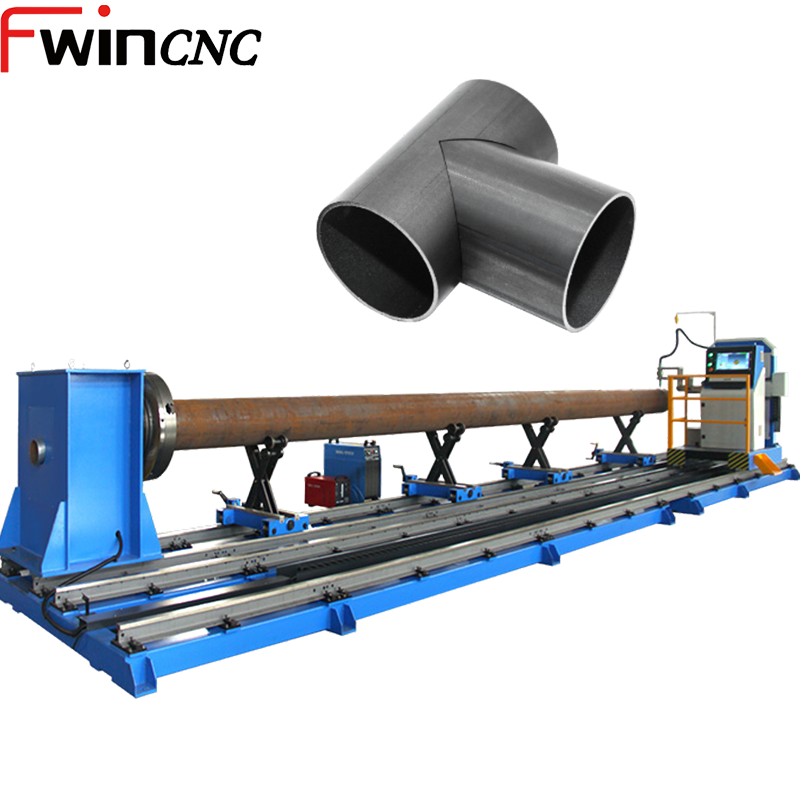

Intersecting Line Round Pipe Tube Plasma Cutting Machine Stair Handrail 6m 12m

The Intersecting line CNC plasma cutting machine is suitable for cutting cylindrical orthogonal, oblique, eccentric and other inertia holes, as well as oval holes on all kinds of tubes, and can cut coherent inertia lines.

The machine is widely used in the production of metal structural parts, electric power equipment, boiler industry, petroleum, chemical industry and other industrial sectors.

1、Can cut a number of different directions, different diameters of cylindrical coherent line holes in the main pipe to meet the branch pipe axis and the main pipe

Eccentric and non-eccentric orthogonal and oblique intersection of branch pipe axis and main pipe axis.

2、Can cut the coherent line end at the end of the branch pipe to meet the conditions of vertical intersection and inclined intersection between the axis of the branch pipe and the axis of the main pipe with eccentricity and non-eccentricity.

Intersection, inclined intersection conditions.

3、Able to cut oblique section end face on round pipe end.

4、Can cut welded elbow on the round pipe, “shrimp section” at both ends of the diagonal section.

5、Able to cut the coherent end of the branch pipe intersecting with the ring main pipe.

6、 Can cut square holes, waist-shaped holes, oval holes in the middle of the round pipe (square holes and waist-shaped holes can be with rounded corners).

7、Able to carry out steel pipe truncation.

8、Can groove the end of the pipe.

9、Able to make two-way, three-way and other pipe joints.

Products Categories

Get A Free Quote

The intersecting line is the main form of steel pipe and pipe and pipe and plate coupling structure in offshore petroleum engineering, and its cutting quality is good or bad for the bonding strength of the conduit frame and block has an important role, so it is necessary to ensure that the intersecting line precision cutting in the process to avoid quality problems when welding.

The traditional practice of intersecting line cutting is completed by hand, the specific construction process is: intersecting line trajectory sampling – the production of templates – workpiece scribing – hand-cutting -Kind of grinding, so the processing method is cumbersome, not only low productivity, high labor intensity, and poor workpiece even after coherent welding can not guarantee product quality.

To solve the above problems of high consumption and low yield, both final CNC intersection cutting should be adopted to improve yield and quality, and necessary improvements should be made with the development of offshore petroleum steel.

Equipment specifications sheet:

| Item | Description | Specification |

| 1 | Cutting pipe diameter range | 50mm-400mm |

| 2 | Cutting pipe wall thickness | Plasma(Optional) |

| 3 | Effective cut length | 12M |

| 4 | Cutting speed | 100~6000mm/min |

| 5 | Pipe loading weight | Within 1000kgs |

| 6 | Move speed | 10~6000mm/min |

Number of linkage axes

| Motion Axis | Motion Axis | Cutting machine linkage shaft |

| X axis | X(Lateral axis) | Pipe fitting rotation shaft |

| Y axis | Y(Longitudinal axis) | The torch moves the shaft horizontally along the tube fitting axis |

| Z axis | Z(Torch lifting axis) | Torch lifting axis |

Driving type and cutting mode:

| 1 | Steel tube transmission mode | The electric drive chuck rotates to match the longitudinal equipment operation |

| 2 | Cutting mode | Plasma(depend on customer’s request) |

| 3 | Lifting mode | Manual |

| 4 | Cutting function | Intersecting line cutting |

Working environment request:

| 1 | Working voltage | AC220±10v |

| 2 | Input power | 3.0KW |

| 3 | Working temperature | -10~50ºC |

| 4 | Relative humidity | 5%~90% no condensation |

Equipment Accuracy

- Main accessories details:

| 1 | Control system | One set of STARCAM pipe cutting system |

| 2 | Bracket chuck | One set of 320C |

| 3 | Machine head assembly | One set |

| 4 | Reducer | One set |

| 5 | Motor | Motor of 110 |

| 6 | Round tube bracket | 5 sets |

| 7 | Rack form | Square tube welding |

Main technical parameters table:

| 1 | Specifications and models | WF-12000*320 |

| 2 | Input power | 220±10%V AC50HZ/60HZ220W |

| 3 | Cutting mode | Plasma |

| 4 | Effective cutting range | Cutting pipe diameter less than 320mm |

| 5 | Chuck specification | 320mm |

| 6 | Cutting speed | 0-5000mm/min |

| 7 | Operating accuracy | ±0.2mm |

| 8 | FASTCAM | Zhuochuang Professional Pipe Cutting Software |

Application

Structure:

Composed by moving frame, power rotating head and cutting class. The running rail is balanced with the rail support by moving the frame so as to improve the cutting accuracy of the machine. The rotating power head is driven up and down by the chuck and the cutting head rotates in reverse to cut the pipe, which can be deflected axially and radially. The movement of multiple axes is controlled by a linkage system to finally cut the pipe.

Rotating pipe end cutting machine structure:

The equipment system is composed of two intersecting cutting machines, three electric trolleys positioned by moving pipe supports, two mobile material car sections, and two width guide rails.

Improved Rotatable Pipe End Cutting Machine Compared with the traditional CNC coherent line cutting machine, the rotatable pipe end automatic cutting machine has greatly improved both the cutting capacity and the cutting quality, but there is the phenomenon of low equipment utilization in the actual operation.

In order to solve this problem, you can increase the corresponding tire rotation support function, thus ensuring that a cutting device corresponds to two supports, cutting is independent of each other, can be in different poles at the same time cutting work, greatly improving the cutting efficiency. Improve the utilization rate of the equipment.