Mini Portable Laser Cutting Machine for Metal

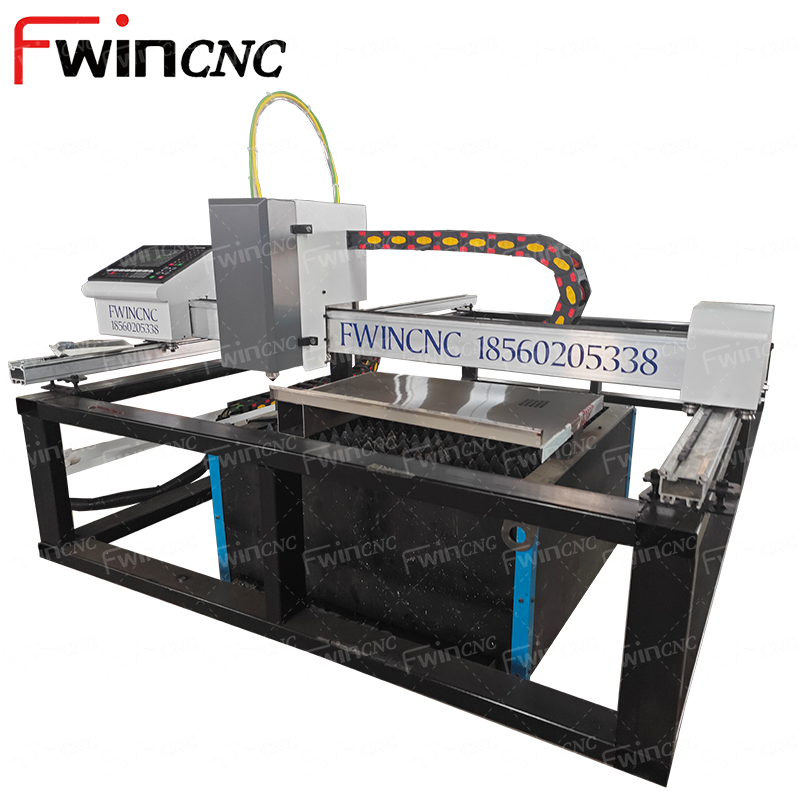

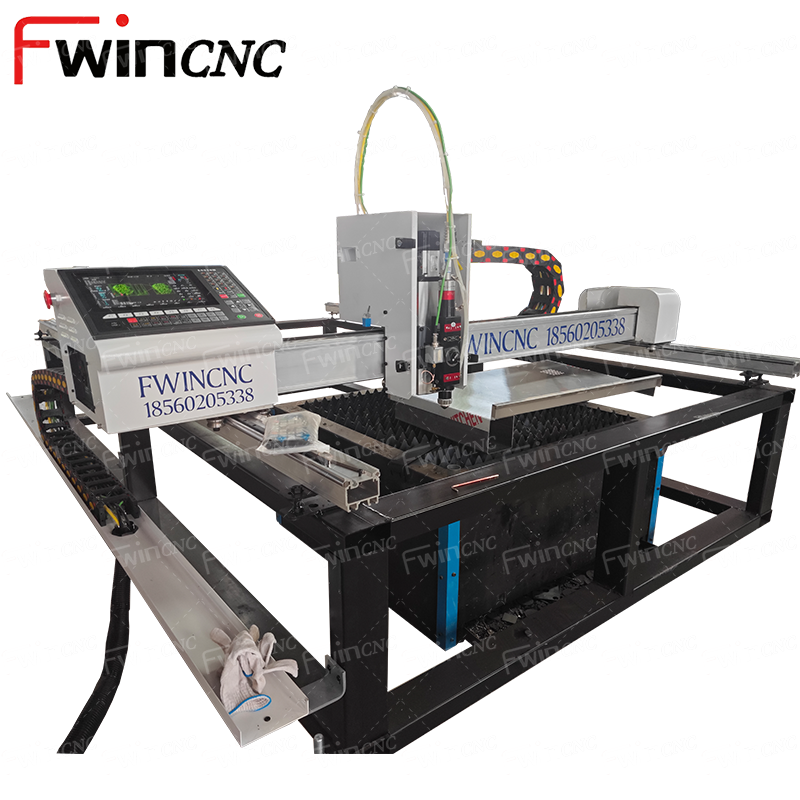

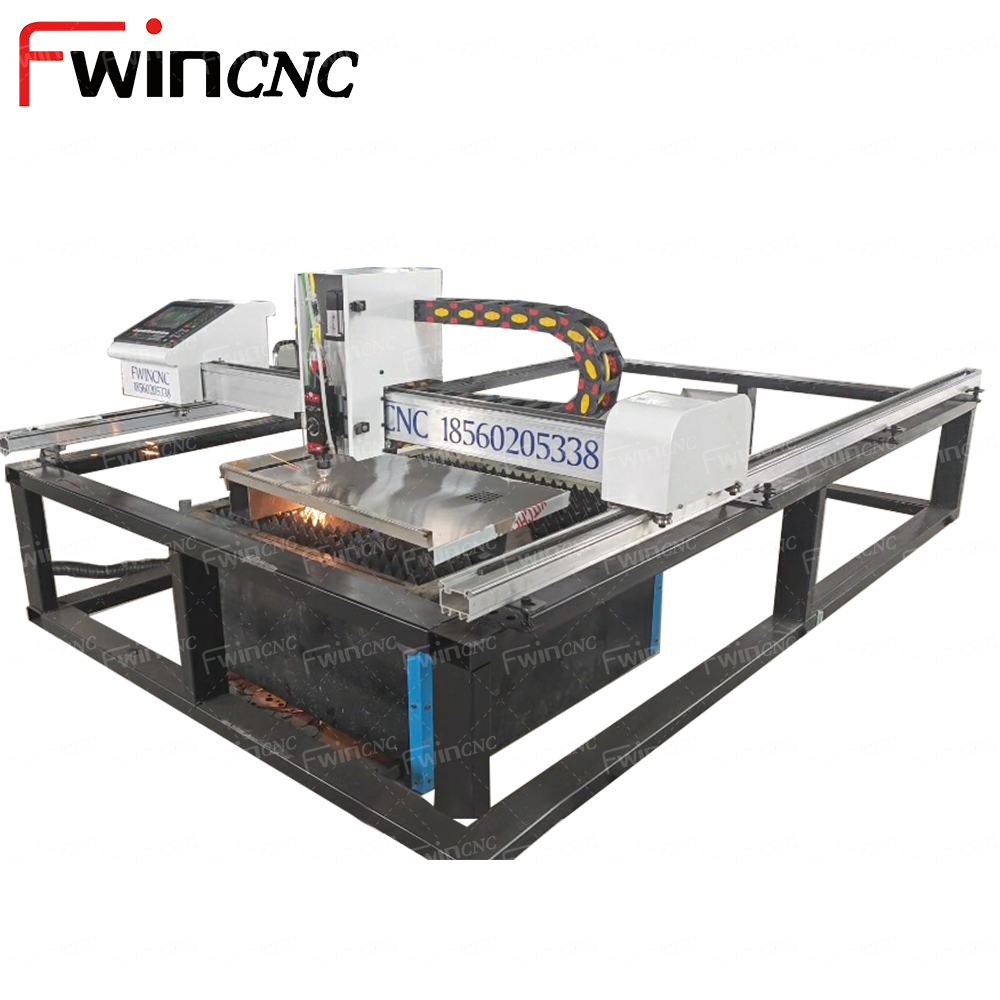

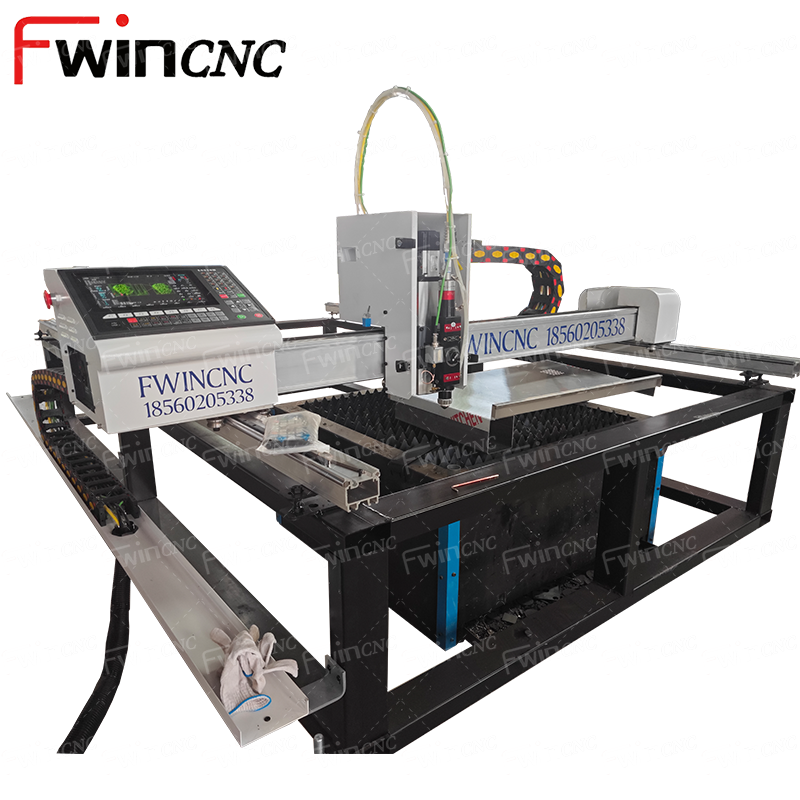

The mini portable laser cutting machine is an innovative portable metal laser processing equipment that integrates laser cutting technology and portable design. It adopts high-precision laser head, which can quickly cut different metal materials, aluminum beams, high-quality tracks, combined with advanced control system, assembled into a portable laser cutting machine, cost-effective, fully functional, easy to use, and is the first choice for transitioning from plasma cutting machine to laser cutting machine.

Mini Portable Laser Cutting Machine Features:

High efficiency. The lighter weight beam can ensure the fast operation of the flat laser cutting machine, improve the processing efficiency, and ensure the processing quality at the same time.

High speed. Aluminum alloy has the characteristics of light weight and high strength, which is conducive to high-speed movement in the processing process, and high flexibility is conducive to high-speed cutting of various patterns under the premise of ensuring high precision.

Mini Portable Laser Cutting Machine Description

Function Material Handling: This machine cuts metal Customization Options: This machine has three power options (1500w, 2000W, 3000w) and can be customized to specific user requirements, including color options such as red, blue or custom colors. Comprehensive Warranty and Support: This machine has a 1-year warranty for the entire machine and a 1-year warranty for core components, and provides a video factory inspection and mechanical test report for safety. Advanced Control System: This machine adopts the “Fangling Latest Laser Dedicated Operating System” and is equipped with a water cooling system to ensure efficient and precise cutting operations, with a user-friendly control system brand

| Index | Parameter |

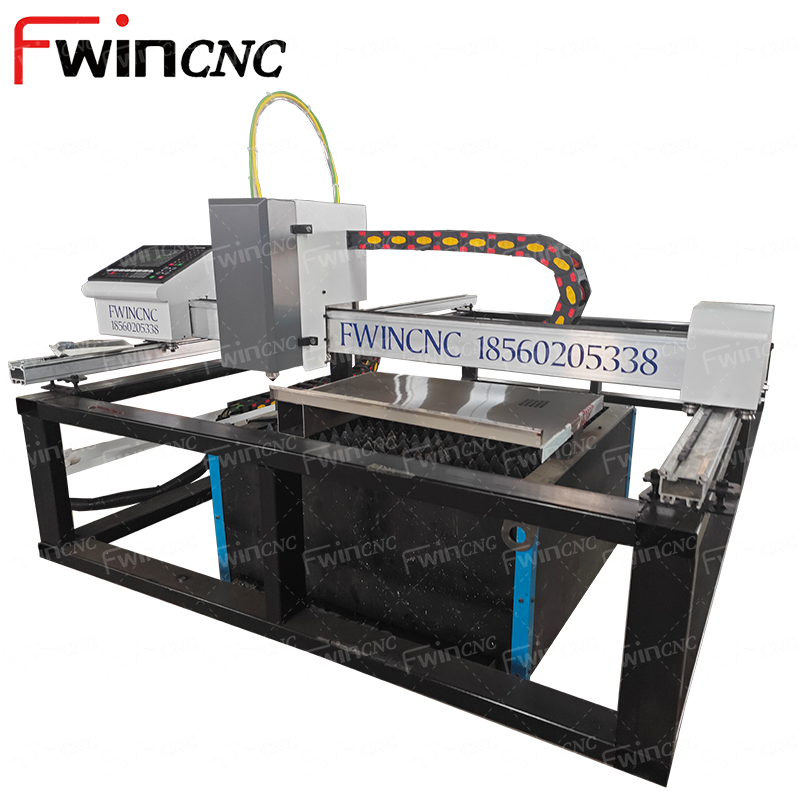

| Model | Allwin-3015 |

| Table | 3000*1500mm |

| X-axis travel | 1500mm |

| Y-axis travel | 3000mm |

| Z-axis travel | 100mm |

| X/Y axis positioning accuracy | 0.08mm |

| X/Y axis repeated positioning accuracy | 0.05mm |

| X/Y axis max.moving speed | 50m/min |

| Max.acceleration | 0.5G |

| Weight | Equipment 550kg+ Optional table 190kg |

| Voltage | 380V/50Hz |

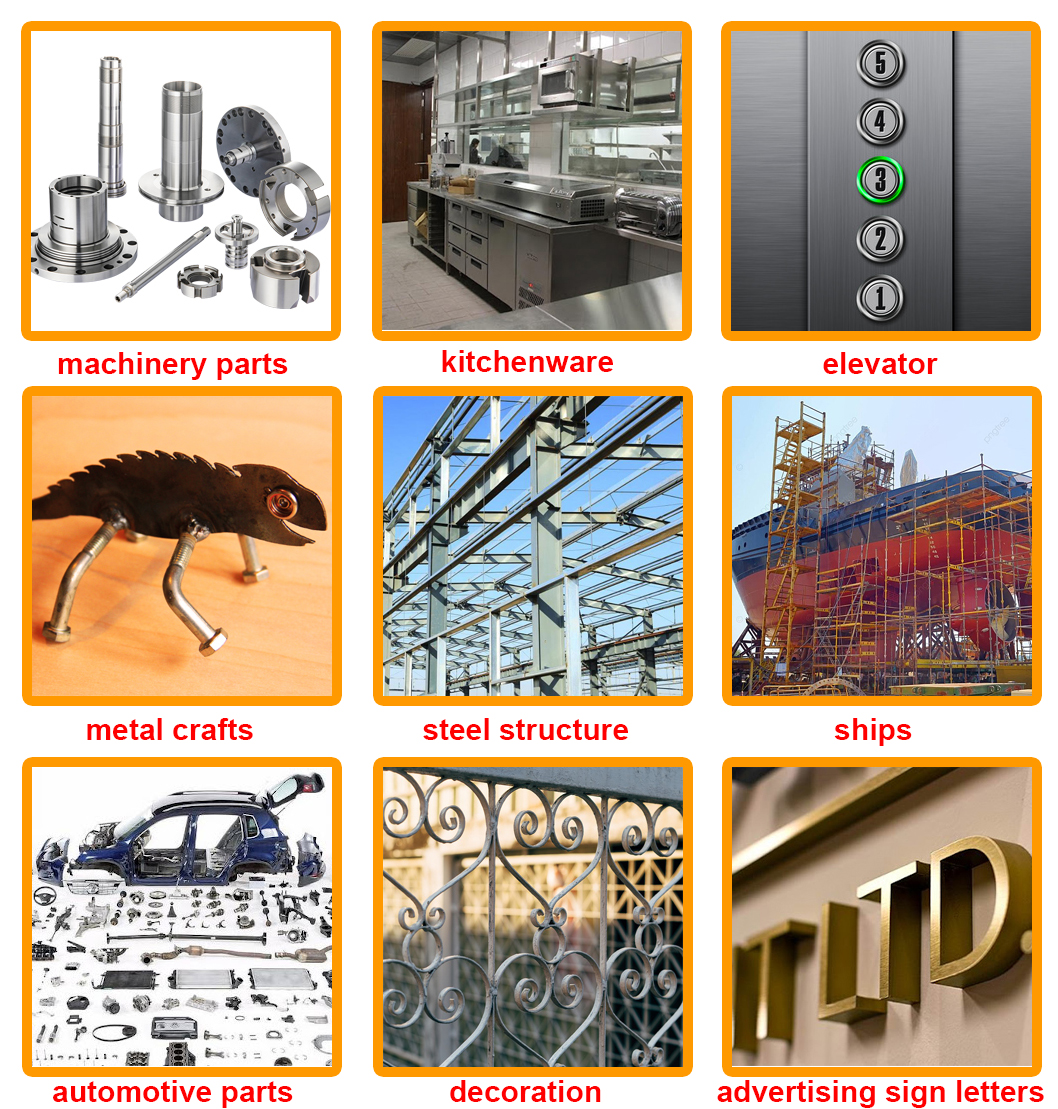

Mini Portable Laser Cutting Machine Applications

Applicable Materials Of Mini Portable Metal Fiber Laser Cutter

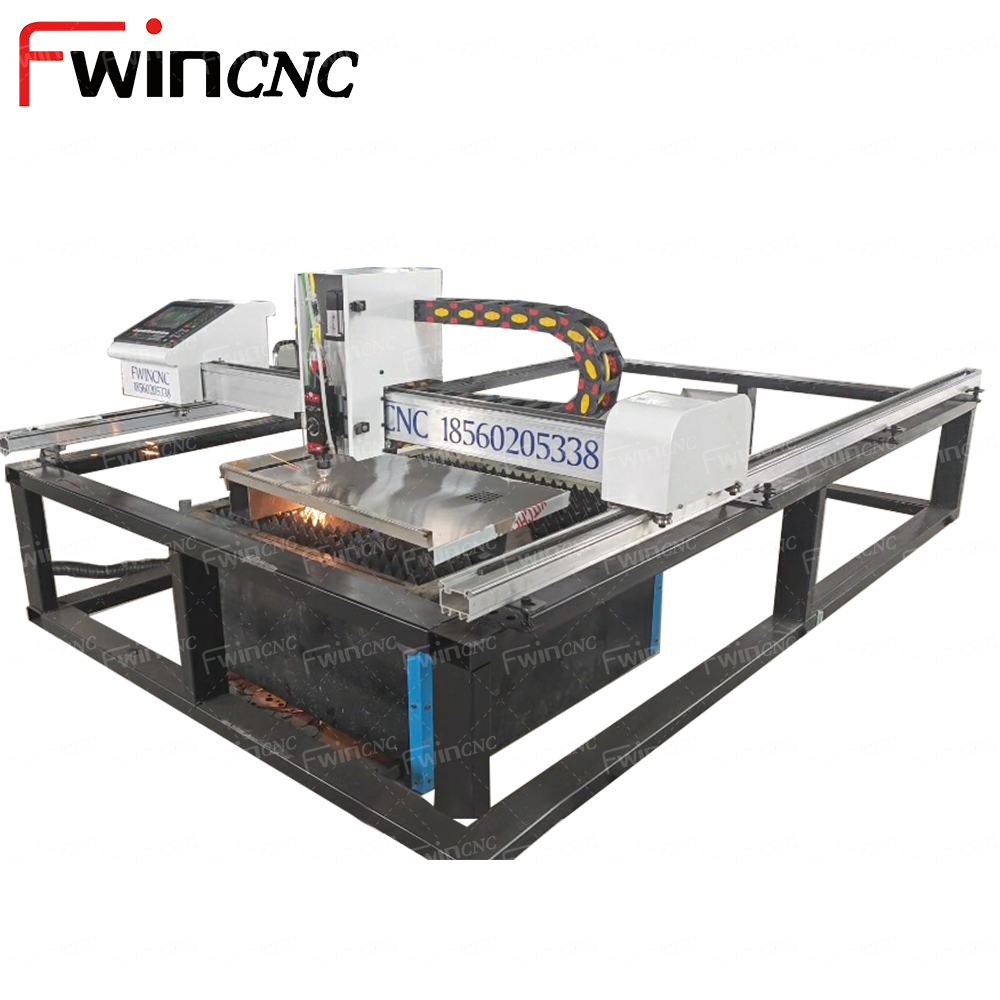

Mini portable metal fiber laser cutter can cut stainless steel, carbon steel, mild steel, alloy steel, galvanized steel, silicon steel, spring steel, titanium sheet, galvanized sheet, iron sheet, inox sheet, aluminum, copper, brass and other metal sheet, metal plate.

Mini portable metal fiber laser cutter is suitable for various industries, such as sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, food machinery, textile machinery, construction machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising, metal exterior processing, kitchenware processing, etc.

1. Laser Power Attenuation

All laser sources experience an annual power attenuation of approximately 2%, regardless of brand. Over prolonged operation, power decline is inevitable. This may stem from the laser source itself or external optical path issues. Regular maintenance of the laser and optical components is essential to restore cutting capacity when power loss impacts production.

2. Focal Position

The focal position critically impacts cutting precision, particularly the focal spot diameter. A smaller focal spot produces a narrower kerf. The spot diameter is proportional to the focal depth of the lens—shorter focal depths yield smaller spots.

3. Nozzle Standoff Distance

The distance between the nozzle and workpiece affects cutting efficiency:

-

Too far: Wastes kinetic energy.

-

Too close: Impairs slag ejection.

-

Optimal range: 0.8mm. For uneven surfaces, real-time height adjustment is required to maintain consistency.

4. Laser Beam Shape & Quality

The conical laser beam creates a tapered kerf. For example, a 0.4mm stainless steel cut will have a much narrower kerf than a 3mm cut. Beam shape is a key factor in cutting precision.

-

Spot size post-focusing: Smaller spots (as tiny as 0.01mm) enable higher precision and finer kerfs.

5. Protective Lens Condition

Inspect the lens for cleanliness—free of water, oil, or debris. Condensation may occur due to ambient humidity or overcooled assist gas.

6. Material Properties & Thickness

-

Surface roughness: Smoother surfaces yield better cuts.

-

Melting point & absorptivity: Materials absorb the 1.64μm wavelength differently.

-

Thickness limits:

-

Optimal range: ≤12mm carbon steel, ≤6mm stainless steel.

-

Thicker materials reduce precision and increase kerf width.

-

7. Cutting Speed

Cutting speed is directly proportional to laser power. Higher speeds require higher power to maintain quality.

8. Assist Gas

-

Pressure & purity: Higher pressure and purity reduce slag adhesion for smoother cuts.

-

Gas selection:

-

Oxygen: Fastest cutting.

-

Nitrogen: Best finish (higher cost).

-

Related Products

Related News

Laser cutting machines are a valuable asset for many industries Laser cutting machine is a valuable asset for many industries, […]

In recent years, the advent of portable laser cutting machines has significantly transformed the landscape of precision cutting in various […]

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]