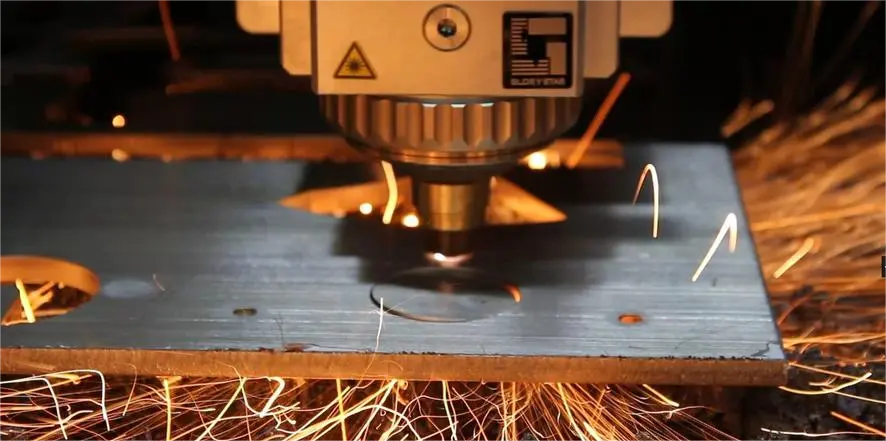

Affordable Heavy Gantry Laser Cutting Machine

Introducing our high-powered, large-area precision cutting heavy gantry laser cutting machine, engineered with an extraordinary leap in accuracy. Provides a variety of configurations and format combinations, which can be customized according to your needs

Key Features:

1.Our CNC Heavy-Duty Gantry Laser Cutting Machine features a wide table, customizable processing width and can slice oversized materials. It offers comprehensive processing of ultra-long parts.

2.The spacious work area of our Gantry Style Laser Cutting Machine accommodates large sheets easily. Due to differences in model and manufacturer, the machine’s dimensions and cutting capacity may vary. However, it is common for this type of machine to handle sheets several meters long and wide.

3.Our Aviation Aluminum Profile Cutting Longitudinal Beam is lightweight, robust, and moves swiftly.

4.It is an excellent choice for cutting large sheets due to its precision, efficiency, and ability to process diverse materials.

Heavy Gantry Laser Cutting Machine Description

The utilization of a dual drive gantry in cutting operations ensures exceptional stability and precision. This advanced technology allows for smooth and accurate movement of the cutting head, resulting in precise cuts even on wide plates. The customized format of the equipment is specifically designed to seamlessly fit into workshop spaces, maximizing efficiency and productivity.

One of the key advantages of this equipment is its increased motion rigidity, which enhances cutting accuracy. This is particularly beneficial for customers looking to improve their workshop production competitiveness. The cutting section is clean and the equipment enables more precise small hole cutting, further enhancing the quality of the finished product.

In addition to its cutting-edge performance, this equipment also promotes an environmentally friendly cutting environment. The cutting process produces minimal smoke and dust, reducing air pollution and creating a healthier workplace. This is especially important in today’s world where sustainability and eco-friendliness are highly valued.

Furthermore, the gantry type installation and deployment of this equipment are quick and efficient. It requires minimal equipment foundation construction, saving time and resources. This ensures straightforward use and maintenance procedures, allowing customers to easily operate and maintain the equipment without any complications.

Overall, the utilization of a dual drive gantry in cutting operations offers exceptional stability, precision, and efficiency. Its customized format, increased motion rigidity, and enhanced cutting accuracy contribute to boosting workshop production competitiveness. Additionally, its clean cutting section, precise small hole cutting, and minimal smoke and dust production create an environmentally friendly cutting environment. The quick installation and deployment process, along with straightforward use and maintenance procedures, make this equipment a valuable asset for any workshop.

Heavy Gantry Laser Cutting Machine Applications

The heavy gantry laser cutting machine ensures efficient laser cutting standards, providing support for the production of various sizes of medium and thick steel plates in industries such as shipbuilding, construction machinery, steel structures, locomotives, agricultural and forestry machinery, electrical manufacturing, petroleum machinery, food machinery, kitchen and bathroom appliances, grain machinery, textile machinery, tool processing, automotive, and laser outsourcing services.

Large processing area

With a large processing area, the cutting length can be extended up to 40 meters and even further with the use of an on-board laser. Additionally, the maximum cutting width can reach 8 meters, making it suitable for batch processing of large-format, simple-profile medium and heavy plate parts.

High processing precision

The high processing accuracy of fiber laser technology allows for precise cutting, especially when compared to plasma machine tools. This enables the processing of finer parts and corners.

Fast processing speed

When it comes to processing speed, medium and heavy plate materials have a clear advantage. This significantly improves processing efficiency, making it the preferred choice for large plate cutting.

High material utilization rate

Furthermore, the narrow kerfs and higher machine precision of laser cutting result in tighter nesting and higher material utilization. This means that more parts can be machined using a laser for the same size of plate.

Cutting section vertical

The vertical cutting section provided by laser cutting eliminates the need for secondary processing, effectively improving production efficiency.

Less dust, efficient and environmentally friendly

Lastly, laser cutting produces less dust and offers high efficiency and environmental protection. The small metal particles and cutting smoke generated during the cutting process can effectively be reduced, ensuring a clean and environmentally friendly cutting process.

Get Free Quote of Gantry laser cutting machine

FWINCNC’s heavy-duty gantry laser cutting machine can cut thin plates at high speed and efficiently, and cut thick plates stably and accurately. It is the perfect choice for your industrial metal cutting.

Related News

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]