Fiber Laser Cutting Mchine for Metal

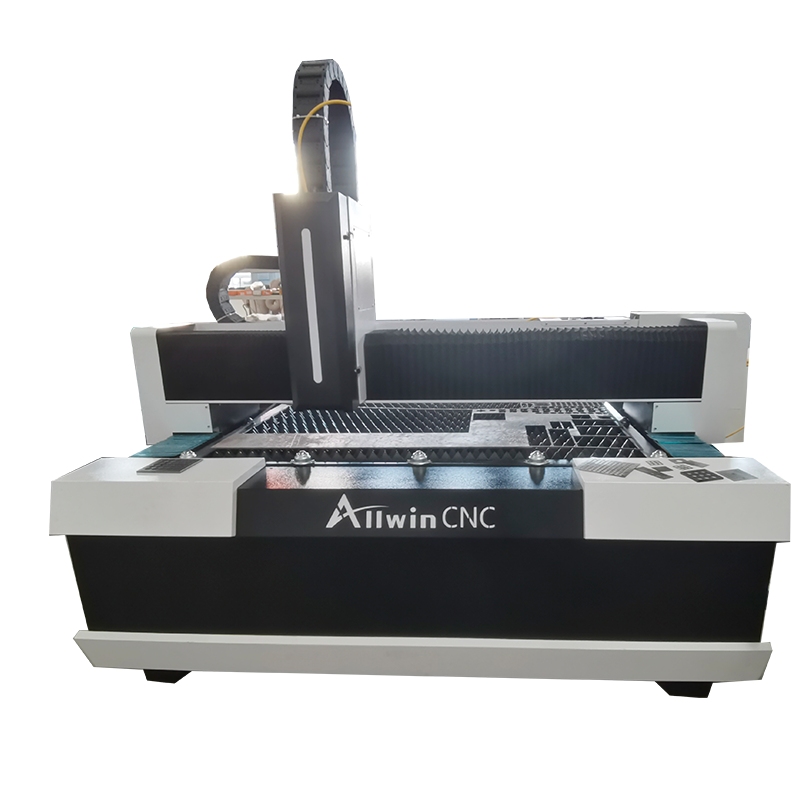

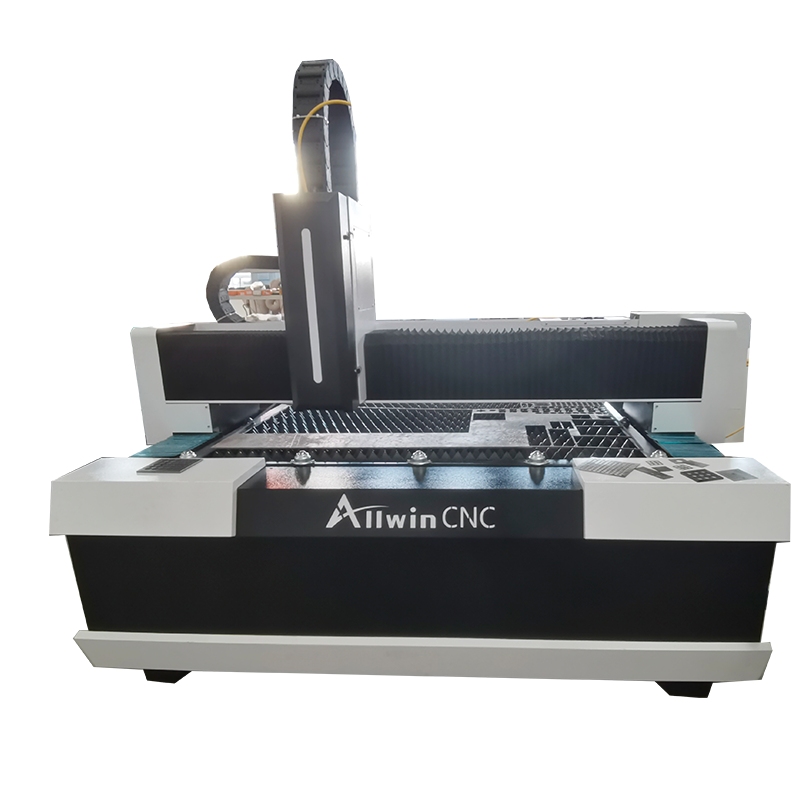

Our fiber laser cutting machine have professional mechanical design, novel appearance modeling and a number of patented technologies, with high degree of refinement, fast speed, small cutting seam, smooth section, simple operation and low energy consumption, are suitable for mass continuous processing and highlight the cutting competitive advantage.

1. The welding bed is constructed entirely from an 8mm plate, featuring a sturdy mortise and tenon structure.

2. The machine is equipped with RAYCUS laser light source and S&A water chiller.

3. The option for partition dust removal is available.

4. Anti-burn components are available as an option.

5. The front electric box is included as a standard feature, while an independent electric box is available as an optional upgrade.

6. Enhancing the air pumping effect, there are 200 air ducts on both sides of the machine.

FEATURES FOR FIBER LASER CUTTING MACHINE

1. The laser power consumption of our cutting machine is incredibly low, ranging from only 0.5-1.5kw per hour. This ensures cost-effectiveness and energy efficiency in your operations.

2. Our cutting machine boasts the best quality laser source from China, guaranteeing high performance, stability, and an impressive service lifespan of over 100,000 hours. With minimal maintenance required, you can rely on its durability. Additionally, it offers high speed and efficiency, enabling thin plate cutting at a rate of over 10 meters per minute.

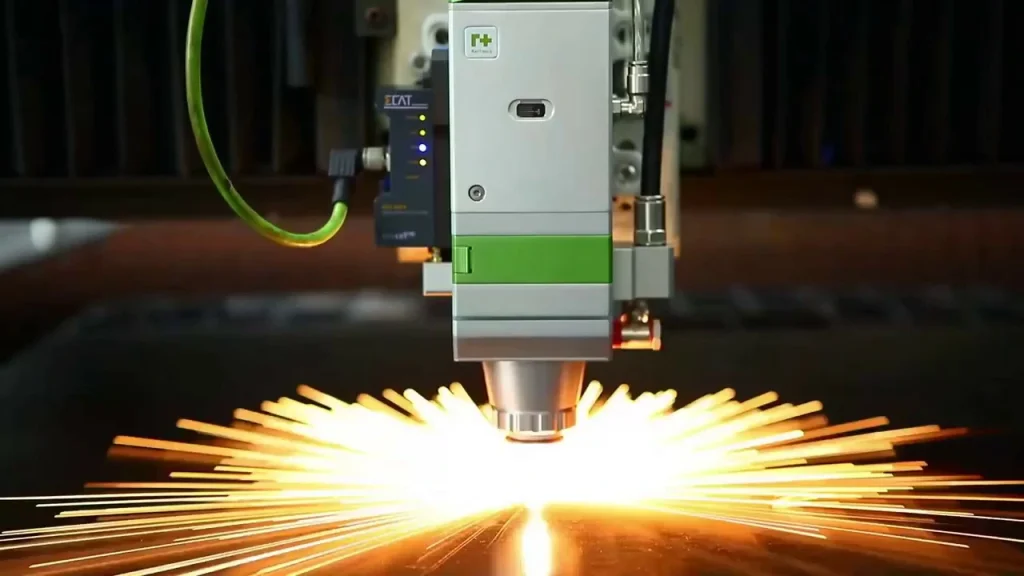

3. To accommodate uneven pieces, our laser head is equipped with an automatic height sensor. This feature ensures precise cutting even on surfaces that are not perfectly flat.

4. We have incorporated an imported ball screw and linear guide rail driving system into our machine. This advanced technology ensures smooth and accurate movement, enhancing the overall performance and precision of the cutting process.

5. Our CNC software is designed to be user-friendly and efficient, allowing for fast programming. With this intuitive software, you can easily create and execute cutting patterns, optimizing productivity.

For those interested in our CNC Fiber Laser Cutting Machine, we offer various options to cater to your specific needs. You can choose the power of the fiber laser cutter, ranging from 500W to 12000W, depending on your requirements. We work with reputable brands such as JPT, RAYCUS, MAX, and IPG for the fiber laser generator.

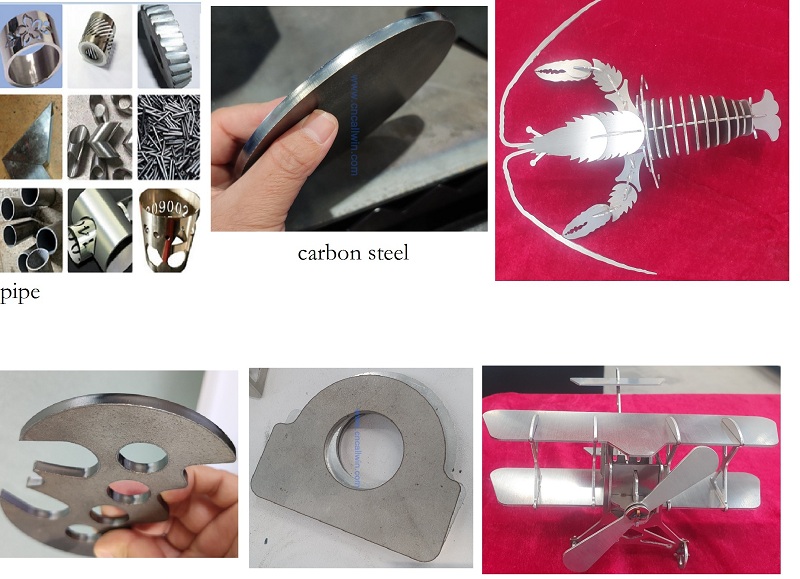

Our cutting machine is compatible with a wide range of materials, including iron, aluminum, carbon steel, stainless steel, copper, and other metal sheet materials. This versatility ensures that you can handle different projects with ease.

Furthermore, we provide optional parts that you can select according to your preferences. These include a rotary axis, exchange working table, and full cover, among others. These additional features enhance the functionality and convenience of the machine.

The standard working area of our machine is 1500mm*3000mm, but we also offer customization options to meet your specific requirements. Whether you need a larger or smaller working size, we can tailor the machine accordingly.

For new users, it is essential to inform us about the thickness of the metal you intend to cut, the desired working area, and the type of metal, such as brass, stainless steel, or mild steel. This information allows us to provide you with the most suitable machine and ensure optimal results.

Technical parameters of fiber laser cutting machine

| No. | machine model:ALLWIN-3015 2000W/6000W/120000W | ||||

| 1 | max working area | 1500mmx3000mm | |||

| 2 | Packing dimension | 2200mmx3700mmx1700mm | |||

| 3 | Laser source | 2KWW/3KW/6KW/12KW/ RAYCUS fiber laser | |||

| 4 | laser head | Swiss RAYTOOLS with auto focus | |||

| 5 | software | Professional FSCUT2000 with Cypcut software | |||

| 6 | motor and driver | Japanese YASKAWA servo motors 850W | |||

| 7 | Reducer | Japan SHIMPO reducer | |||

| 8 | Water chiller | S&A brand with Dual temperature,dual control | |||

| 9 | Rack and pinion | Taiwan brand T-WIN rack and pinion | |||

| 10 | Guild rails | HIWIN GUILDER RAIL | |||

| 11 | Exhaust fan | Blower Exhaust fan | |||

| 12 | motor and driver | Japanese YASKAWA servo motors 850W | |||

| 13 | Air compressor | YES | |||

| 14 | voltage stabilizer | YES | |||

| 15 | Accessories included | RAYCUS FIBER LASER SOURCE 2KW/3KW/6KW | |||

| 1 SET RAYTOOLS LASER HEAD(AUTOMATIC FOCUS) | |||||

| 1 SET WATER CHILLER | |||||

| CYPCUT SOFTWARE | |||||

| INDUSTRIAL COMPUTER | |||||

| FAN | |||||

| LASER PROTECTION GLASSES | |||||

| FIBER LASER CUTTING BED | |||||

The main advantages of laser cutting machines over mechanical processing. A wide range of processing objects, small deformation, high precision, energy saving, and automation are all significant advantages of laser cutting. In addition, there are no tool wear, personalized shape processing, etc. It is no exaggeration to say that laser cutting has obvious advantages over traditional mechanical processing. This is also the key to the wide application of laser cutting machines and the booming market in recent years.

1) Kitchenware industry

The traditional processing methods in the kitchenware manufacturing industry face problems such as low work efficiency, high mold consumption, and high usage costs. The laser cutting machine has fast cutting speed and high precision, which improves the processing efficiency. It can also realize customized and personalized product development, solve the problems of kitchenware manufacturers, and is deeply recognized by kitchenware manufacturers.

2) Automobile manufacturing industry

There are also many precision parts and materials in automobiles, such as automobile brake pads, etc. In order to improve the safety of automobiles, cutting accuracy must be ensured. Traditional manual labor is difficult to achieve accuracy and is inefficient. Laser cutting can be processed in batches quickly and with high accuracy. High efficiency, no burrs, and one-time molding are the reasons why laser cutting machines are widely used in the automotive industry.

3) Fitness equipment industry

The diversity of fitness equipment also places high demands on processing. Various specifications and shapes make traditional processing complex and inefficient. Laser cutting processing has high flexibility and can be used for customized flexible processing of different pipes and plates. The finished product is smooth and burr-free without the need for secondary processing. The quality and efficiency are greatly improved compared to traditional processes.

4) Advertising metal letter industry

Traditional advertising processing equipment is generally used to process advertising fonts and other materials. Due to the unsatisfactory processing accuracy and cutting surface, the probability of rework is quite high. High-precision laser cutting technology eliminates the need for secondary rework, greatly improves work efficiency and saves corporate costs.

5) Sheet metal processing industry

With the rapid development of sheet metal processing technology, traditional sheet metal cutting equipment can no longer meet the current process and cutting shape requirements. Laser cutting has gradually replaced traditional equipment with its advantages such as high level of flexibility and fast cutting speed. Fiber laser cutting machine wide application in sheet metal processing is an inevitable trend.

6) Chassis and cabinet industry

The power distribution cabinets, file cabinets, etc. we see in our daily life are all products produced in a standardized manner with thin plates, which require very high efficiency. However, using a four-station or six-station laser cutting machine is relatively suitable and has high efficiency, double-layer cutting can also be achieved for specific plates.

the power distribution cabinets, fole cabinets, etc. we see in our daily life are all products produced in s standardized manner with thin plates, which require very high efficiency. however, using a four- station or six-station laser cutting machine is relatively suitable and has high efficiency, double-layer cutting can also be achieved for apecific plates.

7) Agricultural machinery industry

With the continuous development of agriculture, the types of agricultural machinery products tend to be diversified and specialized, and at the same time, new requirements are put forward for the manufacturing of agricultural machinery products. The advanced laser processing technology, drawing system and CNC technology of the laser cutting machine not only reduce the production cost of agricultural machinery equipment, but also improve the economic benefits.

8) Shipbuilding industry

In the field of shipbuilding, marine steel plates cut by laser have good seam quality, good verticality of the cut surface, no slag, thin oxide layer, smooth surface, no need for secondary processing, direct welding, and small thermal deformation, curve cutting it has high precision, reduces coordination man-hours, and achieves barrier-free cutting of high-strength ship plates.

What is Fiber Laser Cutting Machine

A metal laser cutting machine is a CNC device used for cutting various metal materials such as sheet metal, metal profiles, and metal tubes. It is considered the most efficient cutting solution for metal manufacturers.

This machine is capable of handling 2D and 3D cutting projects involving materials like hot rolled steel, cold rolled steel, stainless steel, carbon steel, and more. The components of a laser metal cutting machine typically include a rack, laser generator, reflector path, laser cutting head, chiller, control panel, and a CNC system.

How Fiber Laser Cutting Machines Work

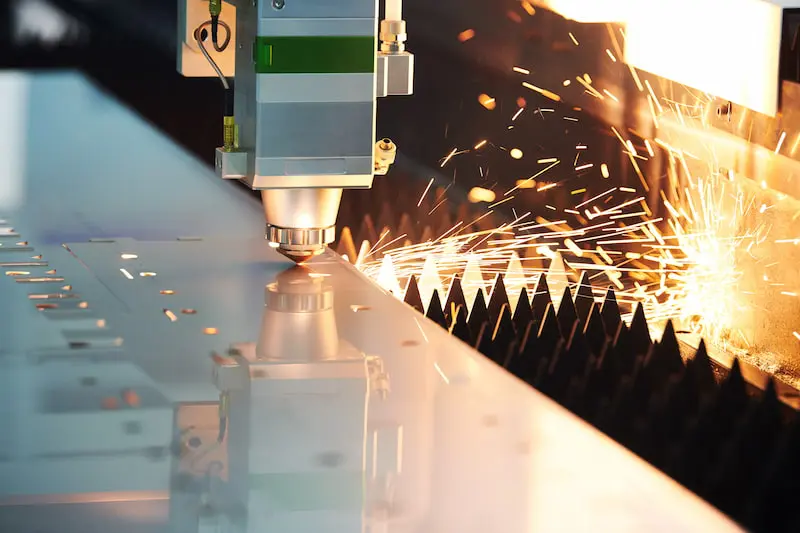

The laser beam is focused into a very small spot with the smallest diameter (can be less than 0.1mm), achieving high power density (can exceed 106W/cm2) at the focal point. At this point, the heat input from the laser beam (through optical energy conversion) far exceeds the portion of the material reflected, conducted, or diffused, rapidly heating the material to the vaporization temperature and evaporating to form a hole.

With the relative linear movement of the beam and the material, the hole is continuously formed with a very narrow width (e.g. about 0.1mm). The thermal impact on the edge is minimal, and there is virtually no workpiece deformation.

In the laser metal cutting process, auxiliary gas suitable for the material to be cut is also added. When cutting steel, oxygen must be used as the auxiliary gas to undergo an exothermic chemical reaction with the molten metal, oxidizing the material while helping to blow away the slag in the seam.

For metal parts with higher processing precision, nitrogen can be used as an auxiliary gas in industry. Most organic and inorganic materials can be cut by laser.

In the metal processing industry, which accounts for a large proportion of industrial manufacturing, many metal materials, regardless of their hardness, can be cut without deformation.

Of course, for highly reflective materials such as gold, silver, copper, and aluminum alloys, which are also good thermal conductors, laser cutting is difficult or even impossible (some difficult materials can be cut using pulsed laser beams, as the material’s absorption coefficient of the beam will sharply increase immediately when the peak power of the pulse wave is high).

What is fiber metal laser cutting machine used for?

A metal laser cutting machine is utilized to concentrate the energy of a laser into a high-density beam of light. This beam is then directed towards the working surface, generating enough heat to melt the material. Simultaneously, a high-pressure gas is used to remove the molten metal, resulting in precise cutting. It is important to note that laser cutting differs fundamentally from traditional machining methods.

The machine employs a laser beam emitted from a laser generator, which is then focused on the workpiece through an external circuit system, creating a high power density laser beam. The heat from the laser is absorbed by the material, causing a rapid increase in temperature. Once the boiling point is reached, the material evaporates and forms pores as the beam and workpiece move relative to each other. Eventually, these pores create gaps in the material.

During the cutting process, the CNC system controls various parameters such as cutting speed, laser power, and air pressure, as well as the motion trajectory. Additionally, an auxiliary gas at a specific pressure is used to blow away the slag produced during cutting. Metal laser cutting machines find extensive applications in various industries, including metal fabrication, education, small businesses, and home-based manufacturing. They are commonly used for sheet metal fabrication, as well as in sectors such as aviation, aerospace, electronics, kitchenware, automotive, and more.

These machines are suitable for cutting a wide range of materials, including carbon steel, stainless steel, tool steel, spring steel, galvanized steel, aluminum, copper, gold, silver, alloys, iron, brass, titanium, manganese, chromium, nickel, cobalt, and others. They are indispensable tools in the metalworking industry, used for creating metal signs, logos, labels, profiles, letters, arts, crafts, gifts, and even for manufacturing metal tools, foils, decorations, and advertising materials.

Get Free Quote of Fiber Laser Cutting Machine

We utilize a superior machine body that enhances the stability of the equipment during operation. The inclusion of a light crossbeam enables faster performance, while the impeccable industrial design aligns perfectly with man-machine engineering principles.

Moreover, the high-quality electrical software control system enhances the cutting precision of the equipment. This machine offers a more comfortable operation, improved performance stability, enhanced durability, increased cutting efficiency, and a wider range of applications.

Related News

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]