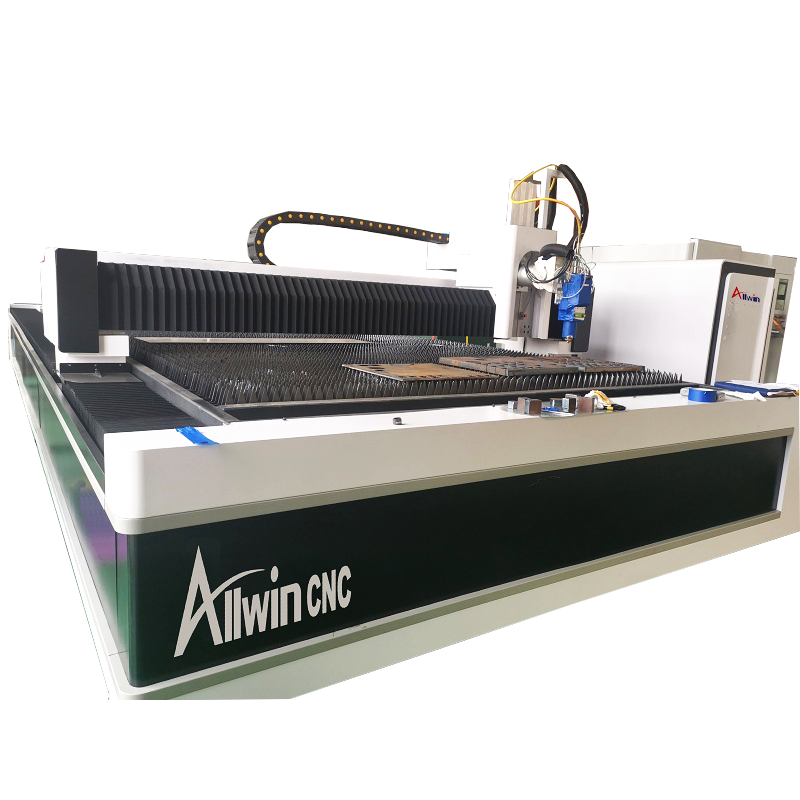

Introduction to the application of bevel laser cutting machine in the manufacturing industry

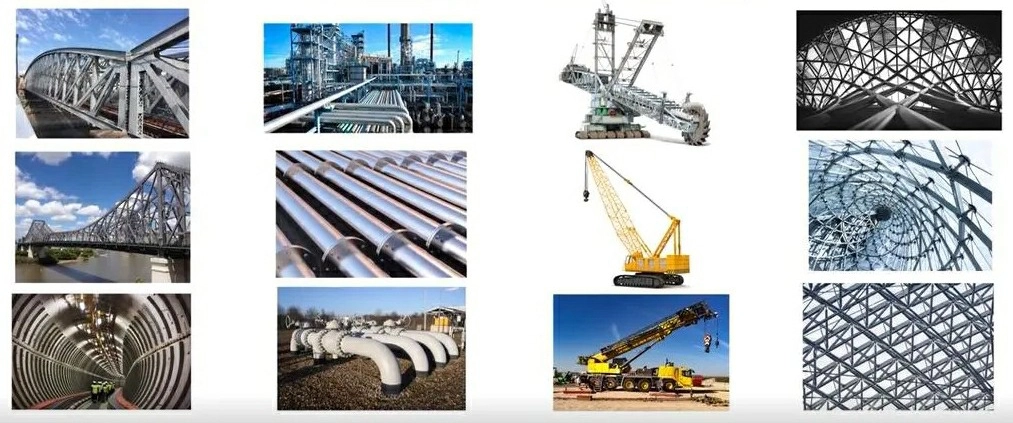

In manufacturing and processing, many parts and components will have a certain angle of groove processing due to the design and structure needs, which is indispensable in automobile manufacturing, industrial and agricultural machinery and ships.

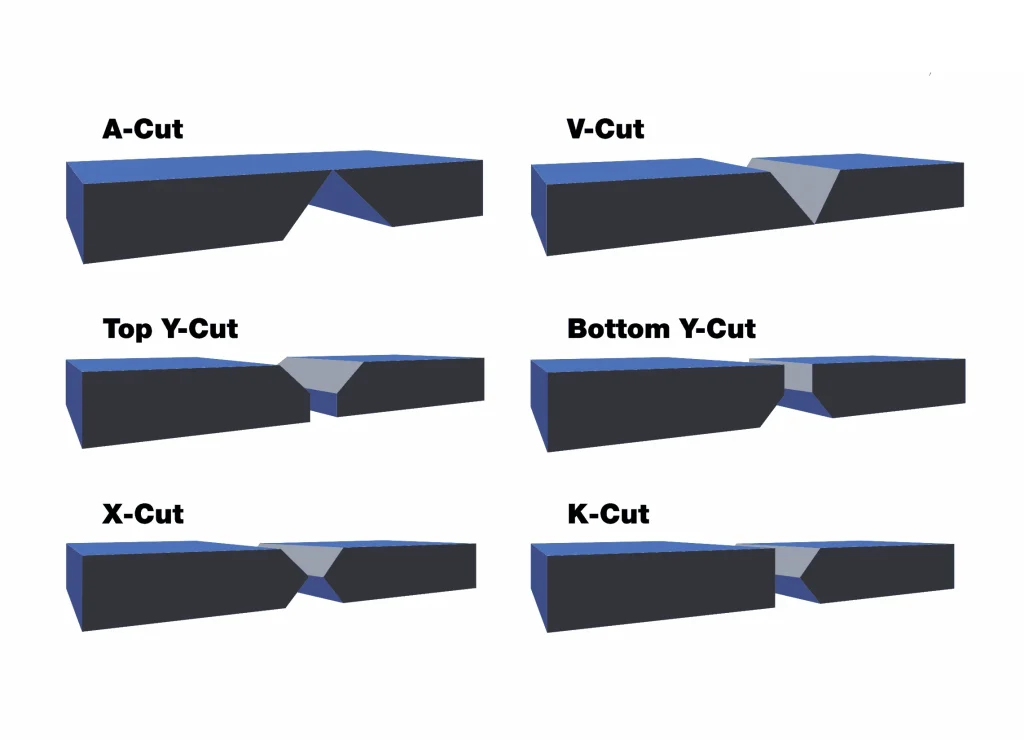

The groove is mainly for the next step of the welding process, which is processed and assembled into a groove of a certain geometric shape at the part to be welded in the weldment, so that the weld can be fully penetrated on the welding thickness.

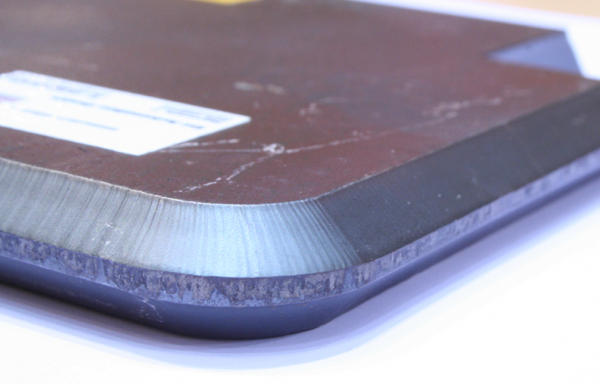

The groove processing mostly adopts flame, plasma and other processing methods, and the common groove forms are V-shaped groove, U-shaped groove, X-shaped groove and Y-shaped groove. These methods produce deep nick marks when cutting bevels, which can easily cause the bevels to not fuse if they are not eliminated before welding.

Generally, this kind of dent more than 3mm must be treated, in the important position, can only be eliminated by grinding, can not allow repair welding, when there are defects in the follow-up processing is very troublesome.

At the same time, flame and plasma processing is a high-heat processing, and the metal plate is easy to produce thermal deformation, and the reverse deformation process needs to be carried out after the groove processing, which is another major difficulty.

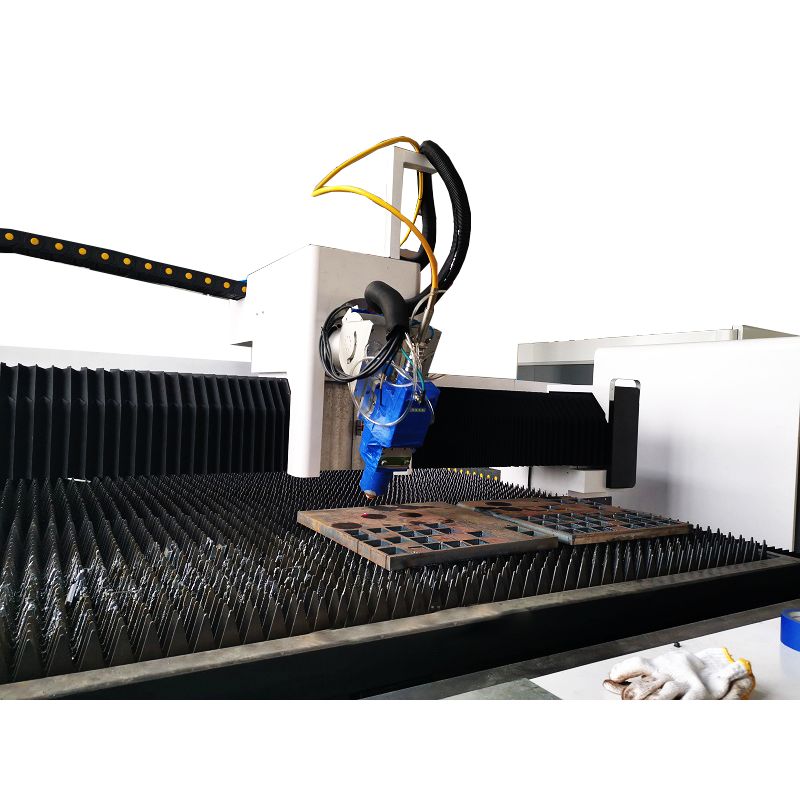

Laser processing is the smallest thermal deformation, the best quailty of the incision of a new type of groove processing means, lcan complete the V, X, Y and other forms of groove at one time, compared with the traditional flame, plasma bevel processing, laser bevel cutting greatly improves the processing efficiency, to ensure the quality of the bevel, but also to save materials.

For example, laser bevel cutting is used in shipbuilding to process T-shaped components of low-alloy steel, which can greatly reduce the weight while ensuring the stability of the ship.

With the large-scale construction machinery, it is necessary to adopt a higher strength low-alloy high-strength steel structure, in order to ensure that the welded joint has good toughness, the welding heat must be reasonably controlled, to avoid the embrittlement of the welded joint.

The traditional hot processing method has not been able to adapt to the current high-strength steel plate forming, the introduction of laser bevel cutting machine in the construction machinery industry is a suitable choice.