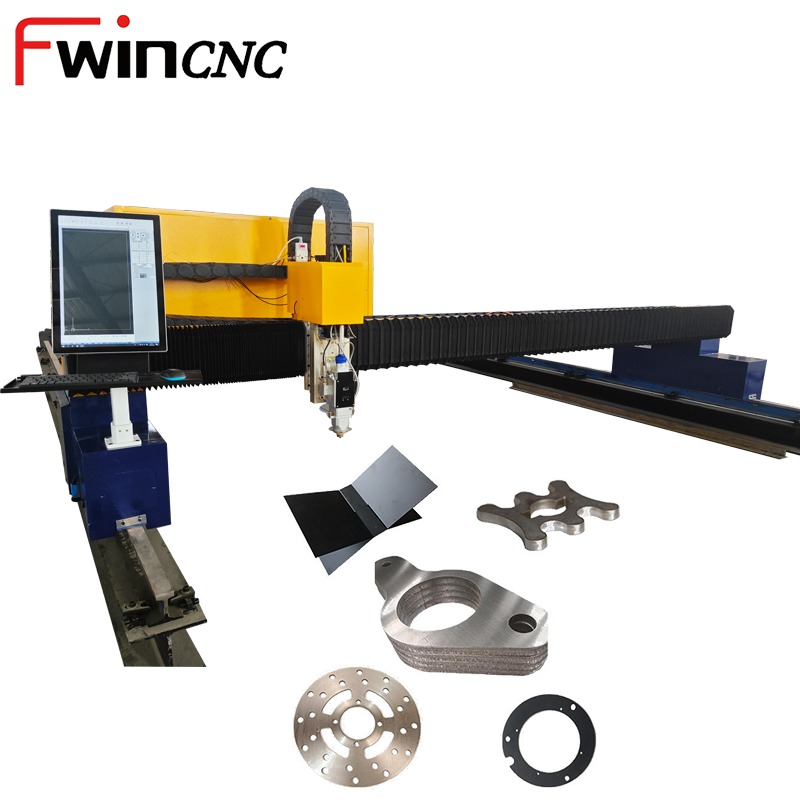

Professional Fiber Laser Cutting Machines Manufacturer in China

Our fiber laser cutting machines feature the latest design, combining high efficiency, large cutting areas, and flexible mobility. Built for precision and durability, they help manufacturers achieve faster production, stable performance, and reliable quality with every cut.

Laser Cutting Machineries Series

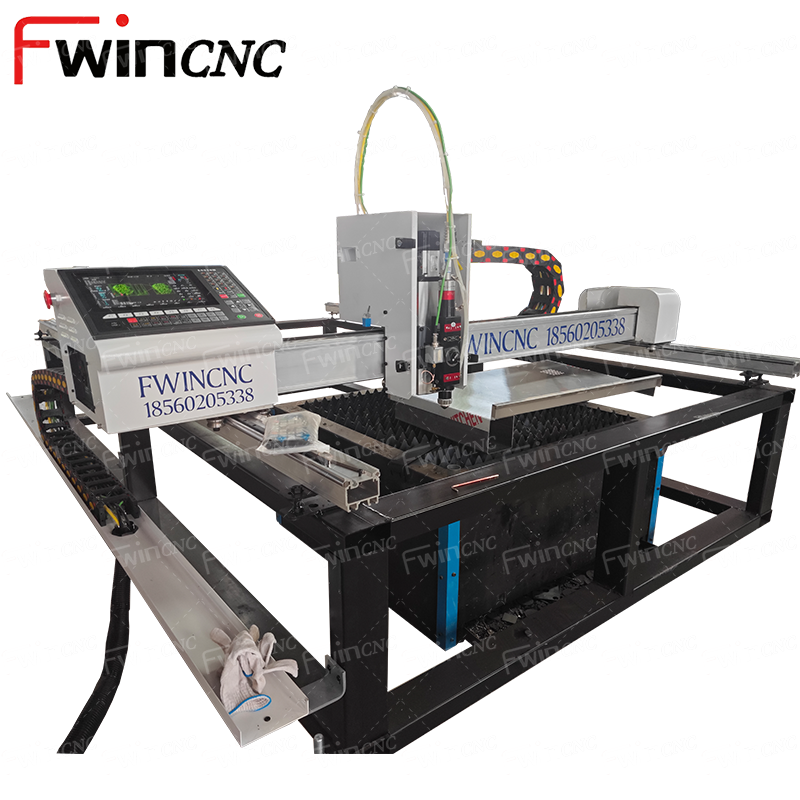

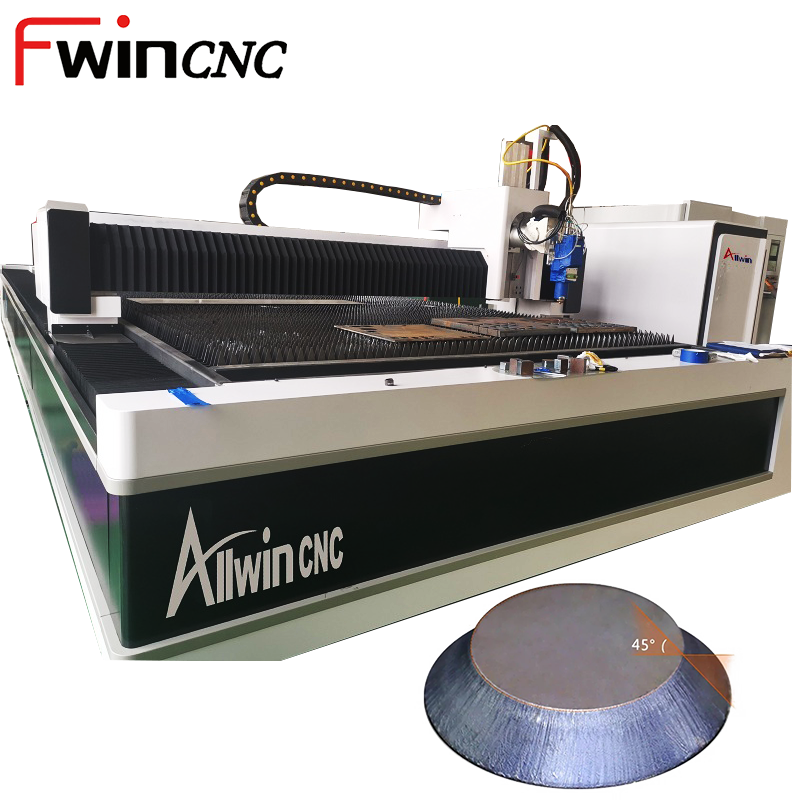

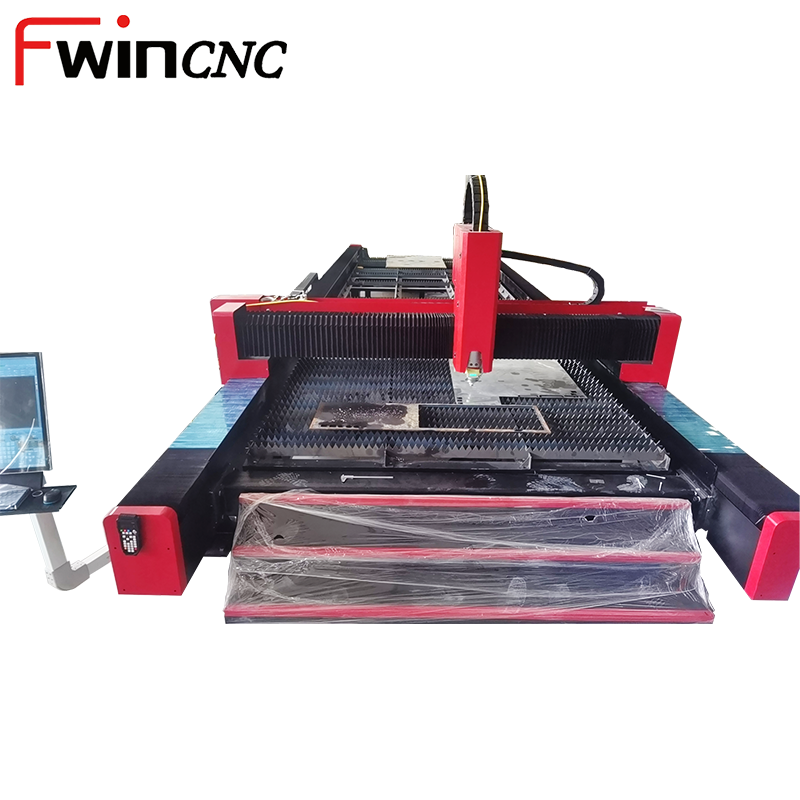

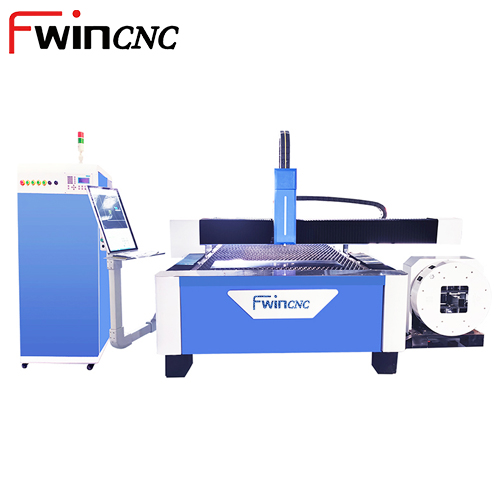

Our FwinCNC laser cutting machines are available in multiple configurations, including portable, gantry, desktop, and large-format floor rail models. Each solution is designed to deliver superior cutting precision, reliable performance, and excellent value for different production needs and budgets.

Higher cutting accuracy with positioning error of ±0.003mm

Low power consumption saves time and power and reduces operating cost

Laser head equipped with an automatic height sensor for handling uneven pieces

High cutting quality smooth cutting surfaces with small cutting seams and can be directly processed for subsequent processing

Efficient utilization of cutting materials. High cutting precision minimizes the amount of waste material, which is both economical and environmentally friendly

How to Choose the Right Laser Cutting Machine for Your Needs

Selecting a laser cutting machine requires careful consideration of your business requirements, material types, budget, and production scale. Here’s a concise guide to help you decide:

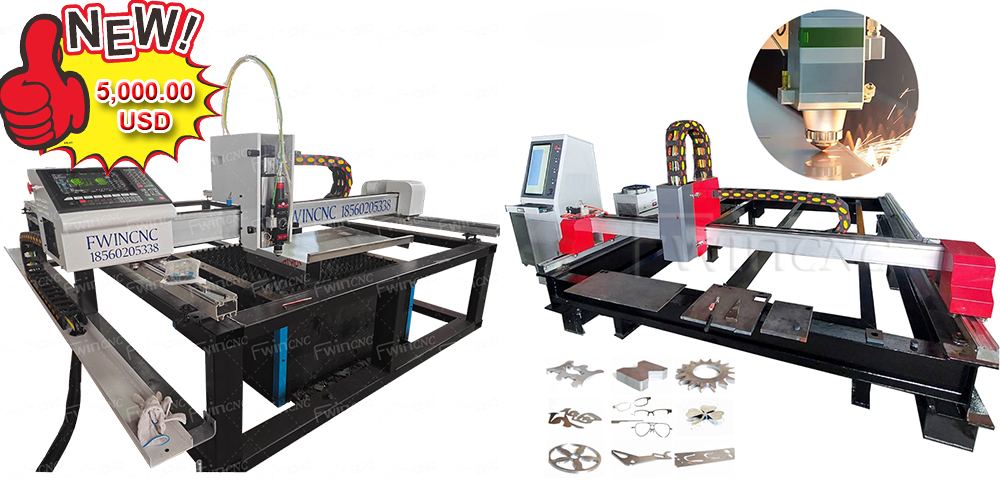

1.Limited Budget, Cutting Thin Sheets (≤6mm)

✅ Recommended Model: Portable Laser Cutting Machine

Power: 1500W (base model, starting at $5,000)

Cutting Capacity: Up to 6mm carbon steel/stainless steel

Advantages: Compact, lightweight, low shipping costs—ideal for small-batch production or mobile operations

✅ Upgrade Option:

3000W/6000W portable models for cutting ≤25mm carbon steel

2.Moderate to High Budget, Cutting Medium-Thick Plates (6–25mm)

✅ Portable vs. Desktop Comparison

Model | Portable | Desktop |

Price | Lower | Higher |

Stability | Moderate | Superior (integrated design) |

Shipping Cost | Low (compact size) | Requires full machine transport |

Cutting Performance | Identical at same power | Identical at same power |

Ideal Use Cases:

Portable: Flexibility and lower upfront costs

Desktop: Fixed-site operations requiring long-term stability

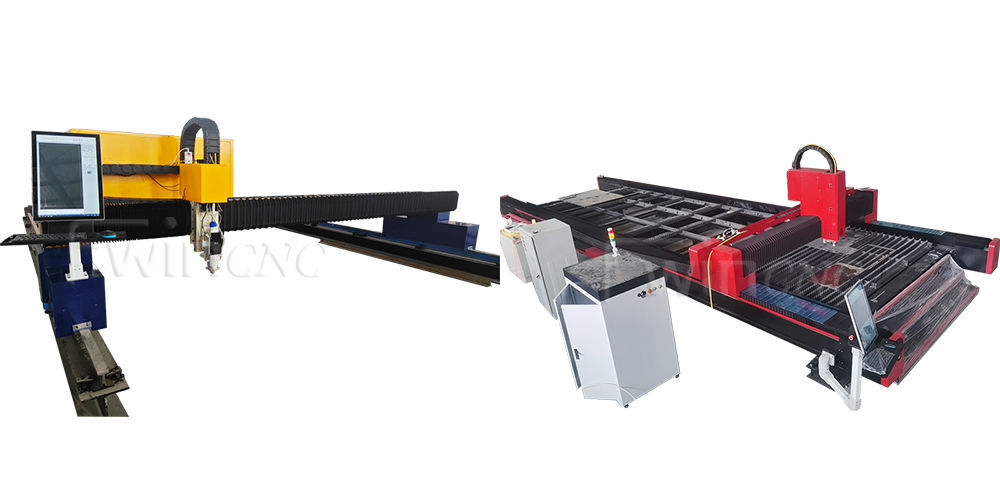

3.High Budget, Cutting Thick Plates (>25mm) or Large Formats

✅ Gantry vs. Ground-Rail Comparison

Model | Gantry | Ground-Rail |

Power | ≥12kW | ≥12kW |

Y-Axis Travel | Extendable (unlimited) | Extendable (unlimited) |

Load Capacity | Standard | Heavy-duty (for ultra-thick plates) |

Installation Cost | Low (modular assembly) | Higher (requires reinforced foundation) |

Ideal Use Cases:

Gantry: Extra-long workpieces or future expansion needs

Ground-Rail: Heavy plates (e.g., 50mm+), high-volume continuous production

Why choose FwinCNC laser cutting manchine?

✅ High Precision & Stability – ±0.05mm repetitive positioning accuracy, with a rigid machine structure and imported linear motors for long-term stable performance.

✅ Intelligent Dynamic Focusing – Automatically adapts to varying material thickness, delivering smooth, burr-free cuts (Ra ≤ 3.2μm).

✅ Reliable Warranty – 2-year machine warranty for peace of mind.

✅ Expert Support – 3 years of online technical assistance from our professional engineers.

How to Prevent Performance Decline in Fiber Laser Cutting Machines?

Key Factors Affecting Performance

Laser Power: Gradual power attenuation over prolonged use directly impacts cutting capability.

Nozzle Standoff Distance: Improper distance between the nozzle and workpiece compromises cutting quality. Maintain optimal spacing for consistent results.

Focal Position: The focal spot diameter must be minimized to achieve a narrow kerf. Adjusting the focus can restore cutting precision.

Overuse & Neglect: Extended overloading, lack of maintenance, and operator errors accelerate performance degradation.

Preventive Measures

Routine Maintenance

Regular upkeep is critical to counteract wear and tear from continuous operation. Follow the manufacturer’s maintenance checklist to preserve machine efficiency.

tandardized Operation

Reputable manufacturers provide operator training to ensure proper handling. Certified personnel reduce operational errors and safety risks while optimizing machine performance.

How to Choose Auxiliary Gases for Laser Cutting?

The selection of auxiliary gases for laser cutting directly impacts cutting quality, efficiency, and cost. Here are the characteristics and applicable scenarios for common auxiliary gases:

Oxygen (O₂)

- Suitable Materials: Carbon steel, low-alloy steel

- Characteristics:

- Oxidation Reaction: Exothermic reaction with metal increases cutting speed (especially effective for thick plates).

- Cut Edge Features: Slight oxidation layer (black or dark), requiring post-processing.

- Cost: Low (industrial oxygen is inexpensive).

- Disadvantages: Not suitable for stainless steel or aluminum (severe oxidation).

Nitrogen (N₂)

- Suitable Materials: Stainless steel, aluminum, titanium alloys, galvanized sheets

- Characteristics:

- Inert Protection: Prevents oxidation, resulting in smooth, burr-free cut edges (suitable for direct welding or coating).

- Purity Requirement: ≥99.9% (lower purity may cause yellowing of cut edges).

- Cost: Higher (especially for high-purity nitrogen).

Compressed Air

- Suitable Materials: Thin carbon steel, non-metals (acrylic, wood)

- Characteristics:

- Economical: Lowest cost (no additional gas source required).

- Cut Edge Quality: Between oxygen and nitrogen, with slight oxidation.

- Applicable Scenarios: General processing where cut edge quality is not critical.

Argon (Ar)

- Suitable Materials: Titanium alloys, nickel-based alloys (high-temperature alloys)

- Characteristics:

- Complete Inertness: Prevents oxidation or nitriding of high-temperature materials.

- Cost: Very high, used only for special materials.

Mixed Gases (e.g., O₂ + N₂)

- Applicable Scenarios:

- Thick Carbon Steel: A small amount of nitrogen mixed with oxygen can reduce slag and increase speed.

- Medium-thick Stainless Steel: Primarily nitrogen with a small amount of oxygen to improve cutting stability.

Material

Gas Cutting quality Cost carbon steel(≤12mm) O₂ General (Oxidized) Low carbon steel(>12mm) O₂+N₂ Great Medium Stainless steel/aluminium N₂ Good (no oxidation) High Titanium alloy Ar Excellent Extremely high Non-metallic/thin carbon steel Compressed air General Lowest

- Applicable Scenarios:

Laser Cutting Machine Applications

-

Automotive – Efficient cutting of car body parts and precision components.

-

Aerospace – High-precision processing of lightweight alloys and complex parts.

-

Electronics – Fine cutting for delicate materials and miniaturized products.

-

Manufacturing – Fast, accurate, and flexible cutting for diverse industries.

FAQ

They can cut various metals, including stainless steel, carbon steel, aluminum, and copper, with high precision and clean edges.

Yes. Our fiber laser cutters support angled (bevel) cuts and complex patterns.

Absolutely. We offer installation guidance, operator training, and ongoing after-sales support to ensure smooth operation and optimal performance.