The application of laser technology has emerged as a game-changer in the manufacturing processes of automobiles

The automotive industry has always been at the forefront of technological advancements, constantly seeking ways to enhance productivity and improve product quality. In recent years, the application of laser technology has emerged as a game-changer in the manufacturing processes of automobiles. Laser cutting machines and laser welding machines have become indispensable tools, revolutionizing the way automotive components are produced.

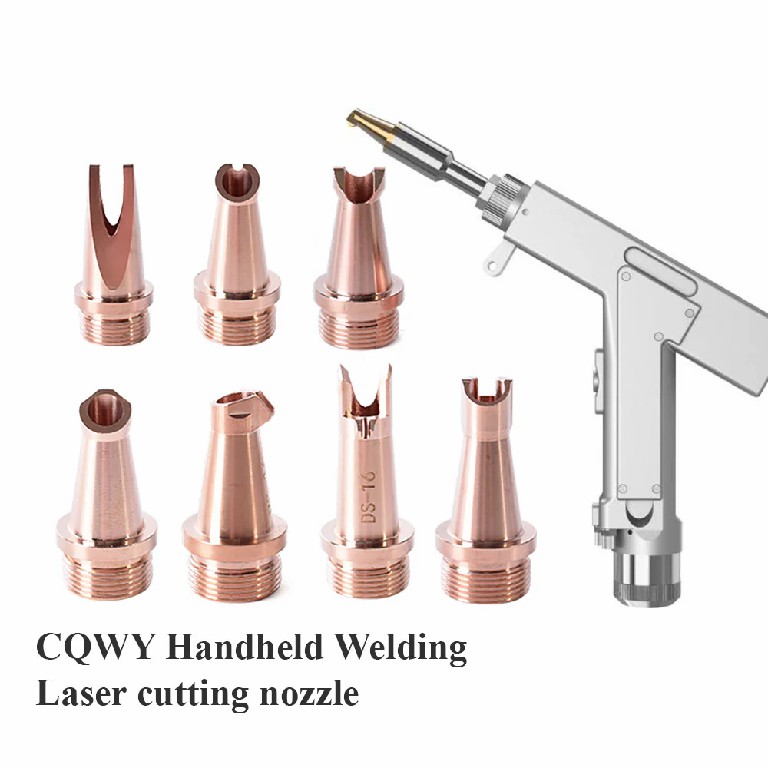

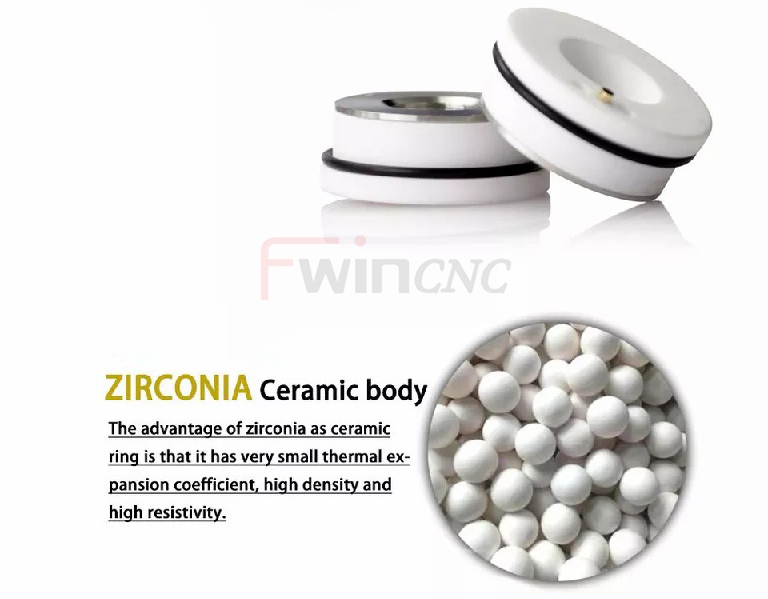

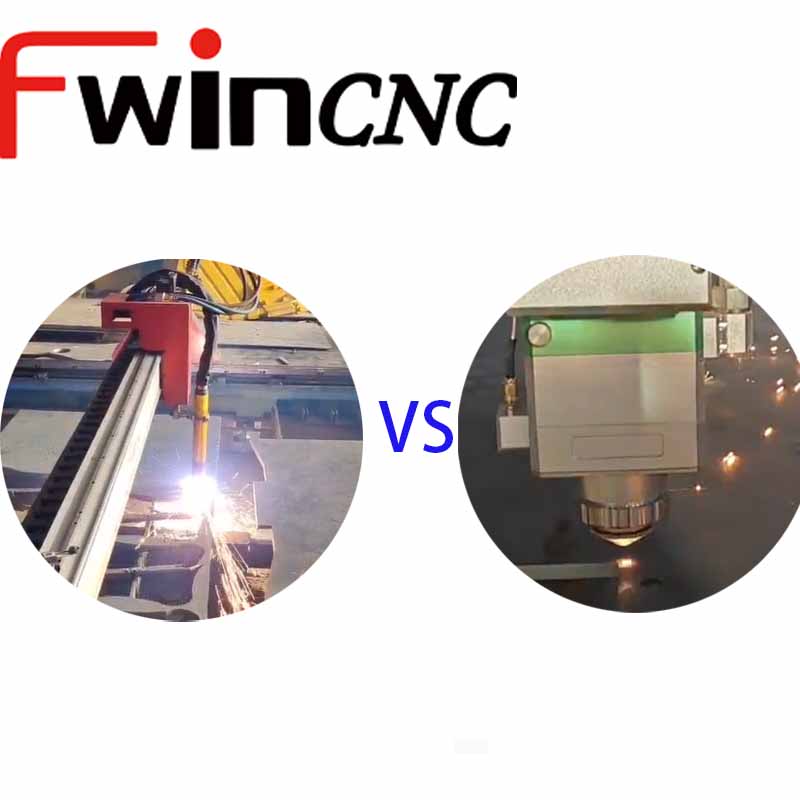

Laser cutting machines are capable of precision cutting of various materials used in automotive manufacturing, such as steel, aluminum, and composited. This level of precision allows for the creation and more reliable products. Additionally, the speed and efficiency of laser cutting machines contribute to increased productivity on the production line, reducing lead times and overall manufacturing costs.

Similarly, laser welding machines have transformed the way automotive components are assembled. By using high-energy laser beams to join metal parts, these machines offer numerous advantages over traditional welding methods. The non-contact nature of laser welding minimizes material distortion and reduces the need for post-welding finishing processes. This results in stronger and more durable welds, ultimately enhancing the overall quality and performance of automotive components.

One of the key benefits of incorporating laser technology in automotive manufacturing is the ability to achieve greater design flexibility. With laser cutting and welding machines, automotive manufacturers can explore innovative designs and geometries that were previously unattainable using conventional manufacturing techniques. This flexibility enables the production of lightweight yet structurally robust components, contributing to improved fuel efficiency and overall vehicle performance.

Furthermore, the integration of laser technology in automotive manufacturing aligns with industry trends towards sustainable and environmentally friendly practices. Laser cutting and welding processes produce minimal waste and consume less energy compared to traditional manufacturing methods, making them more eco-friendly and cost-effective in the long run. As the automotive industry continues to prioritize sustainability, the adoption of laser technology serves as a step towards achieving greener manufacturing practices.

In addition to the technical advantages, the implementation of laser cutting and welding machines in automotive manufacturing also brings about improvements in worker safety. With reduced exposure to hazardous fumes and decreased physical strain from manual labor, employees in automotive production facilities experience a safer and healthier work environment. This not only enhances the overall well-being of workers but also contributes to higher levels of productivity and efficiency on the factory floor.

As the demand for high-quality automobiles continues to grow, automotive manufacturers are increasingly turning to laser technology to meet these expectations. The precise and reliable nature of laser cutting and welding machines ensures that each component meets stringent quality standards, ultimately leading to greater customer satisfaction and brand loyalty. By embracing laser technology, automotive companies can differentiate themselves in a competitive market by delivering superior products that exceed industry benchmarks.

Looking ahead, the future of laser technology in the automotive industry holds even more promise. Advancements in laser systems and automation technologies are expected to further enhance manufacturing capabilities, enabling faster production cycles and greater customization options. Additionally, as research and development in laser technology continue to progress, new applications and innovations are likely to emerge, opening doors to even more possibilities for improving productivity and product quality in the automotive sector.

In conclusion, the integration of laser cutting and welding machines has significantly impacted the automotive industry by enhancing productivity and product quality. These advanced laser technologies have revolutionized manufacturing processes, enabling automotive companies to produce high-performance vehicles with greater efficiency and precision. As the automotive industry continues to evolve, laser technology will undoubtedly play a pivotal role in driving innovation and shaping the future of automobile production.

Contact Information

- Daucus

- E-mail:[email protected]

- Whatsapp:+86 199 0541 9818