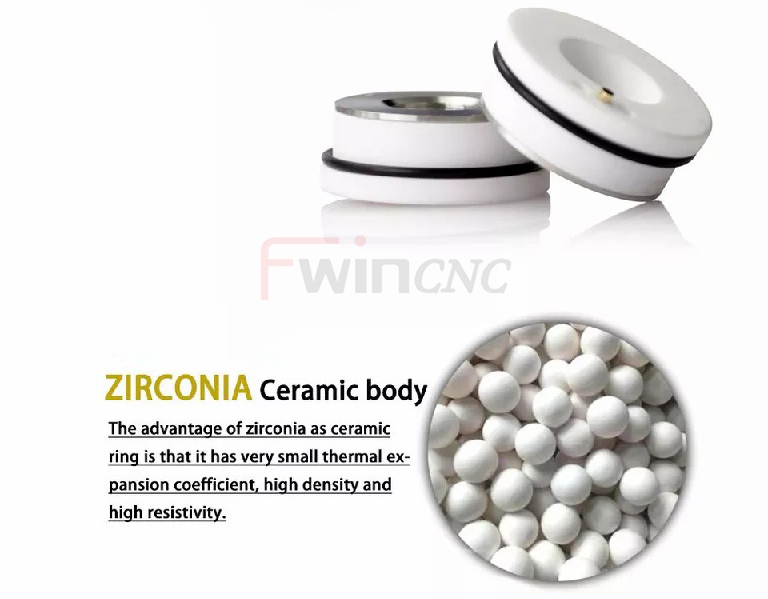

What is laser ceramic ring?

The ceramic ring is a commonly used accessory of laser cutting machine, the laser ceramic ring is installed on the laser cutting head above the nozzle and below the sensor, responsible for transmitting and collecting the cutting signal emitted by the nozzle, the ceramic ring of the laser cutting machine is used to prevent the ceramic ring above the cutting head from being damaged when the laser nozzle collides with other objects. The ceramic ring is a consumable part, but it effectively ensures the safety of the valuable parts!

Ceramic Ring Composition

Ceramic body

There are two primary raw materials used in the fabrication of ceramic bodies: zirconia and alumina. Zirconia, which is slightly more costly, offers several benefits when used to create ceramic rings.

These include an extremely low coefficient of thermal expansion, making it highly resistant to heat; a high density that enhances its durability against impacts and wear; and a high electrical resistivity.

These properties make zirconia-based ceramic bodies particularly effective in ensuring the insulation of critical components and the cutting head, thereby significantly reducing the wear and tear on the cutting head.

On the other hand, alumina is more cost-effective but has a comparatively shorter lifespan.

Stainless steel sheet

The extensive surface area of the stainless steel sheet ensures comprehensive contact with the nozzle, which facilitates the precise and rapid transmission of electrical signals to the copper needle. Thin stainless steel sheets require specialized industrial processing to maintain their integrity and prevent deformation.

Copper rods

Copper rods serve as conduits to relay the electrical signals gathered by the stainless steel sheet to the internal transmission lines within the laser head, ensuring that the controller can adapt to changing conditions.

For the propagation of electrical signals, high conductivity is essential, which is why gold plating is an effective approach.

How to Replace a Ceramic Ring?

To replace a ceramic ring, follow these steps:

- Begin by unscrewing the nozzle.

- Next, unscrew the lock nut that secures the ceramic ring. During this process, it is important to keep your fingers on the old ceramic ring to prevent it from falling vertically due to the torque.

- When installing the new ceramic ring, ensure that the copper post is aligned with the induction hole at the base of the cutting head. A correctly positioned ceramic ring should be level, exhibit some flexibility, and not be able to rotate side to side.

- Hold the ceramic ring in place with your fingers and tighten the lock nut.

- Finally, screw the nozzle back on to complete the installation.

Post-installation, it is essential to calibrate the beam path to prevent any deviation in the light output.