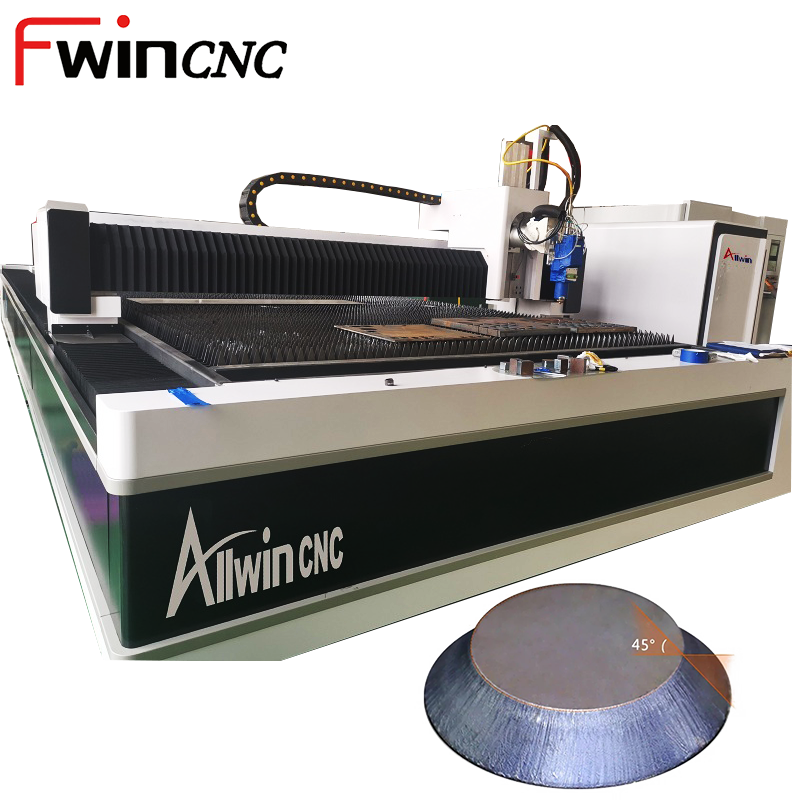

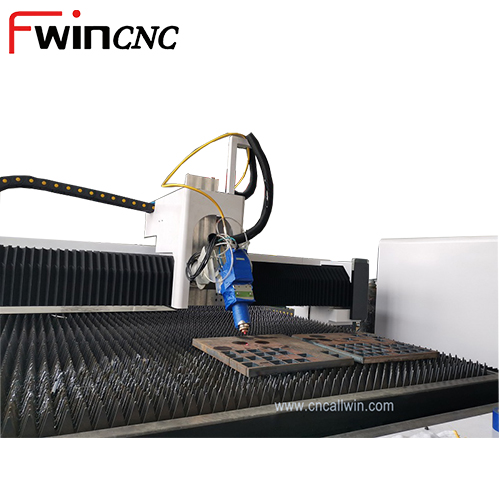

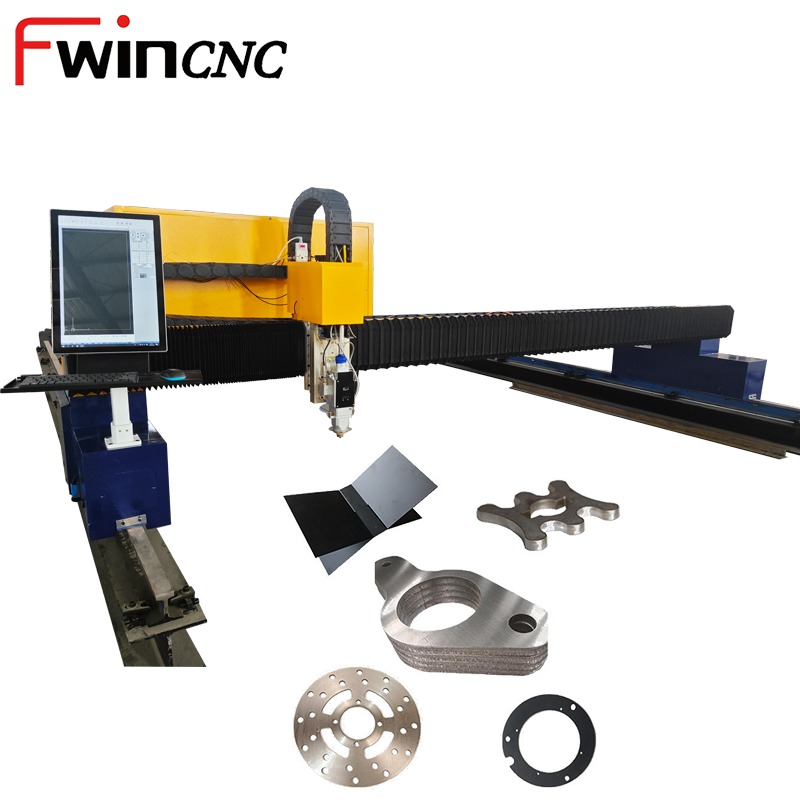

Bevel Laser Cutting Machine in Manufacturing Applications

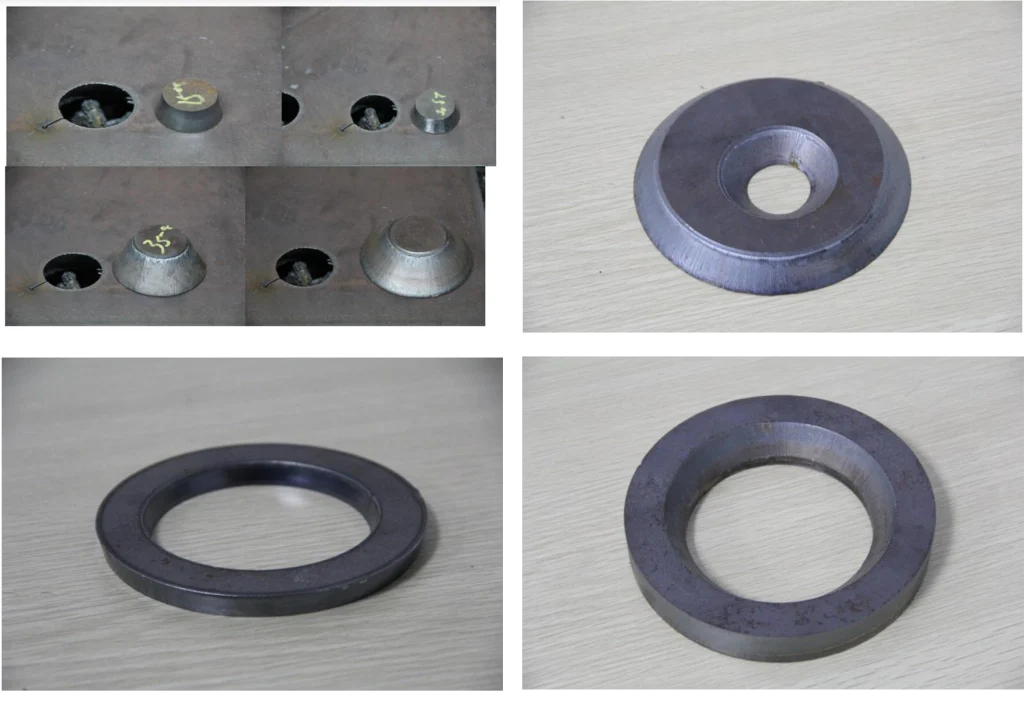

In modern manufacturing, many components require angled grooves for structural design or assembly, which is essential in automobile, industrial machinery, agricultural machinery, and shipbuilding. These grooves prepare parts for precise welding, ensuring full penetration and strong joints.

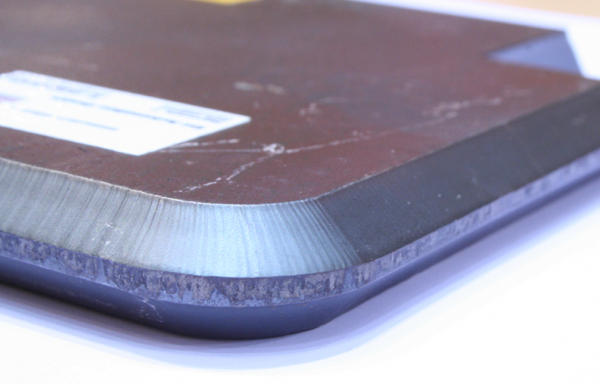

Traditional methods like flame or plasma cutting often leave deep nick marks, cause thermal deformation, and require additional grinding or rework—leading to inefficiency and material waste.

Laser bevel cutting offers a superior alternative:

-

Minimal thermal deformation, preserving the integrity of high-strength steel plates.

-

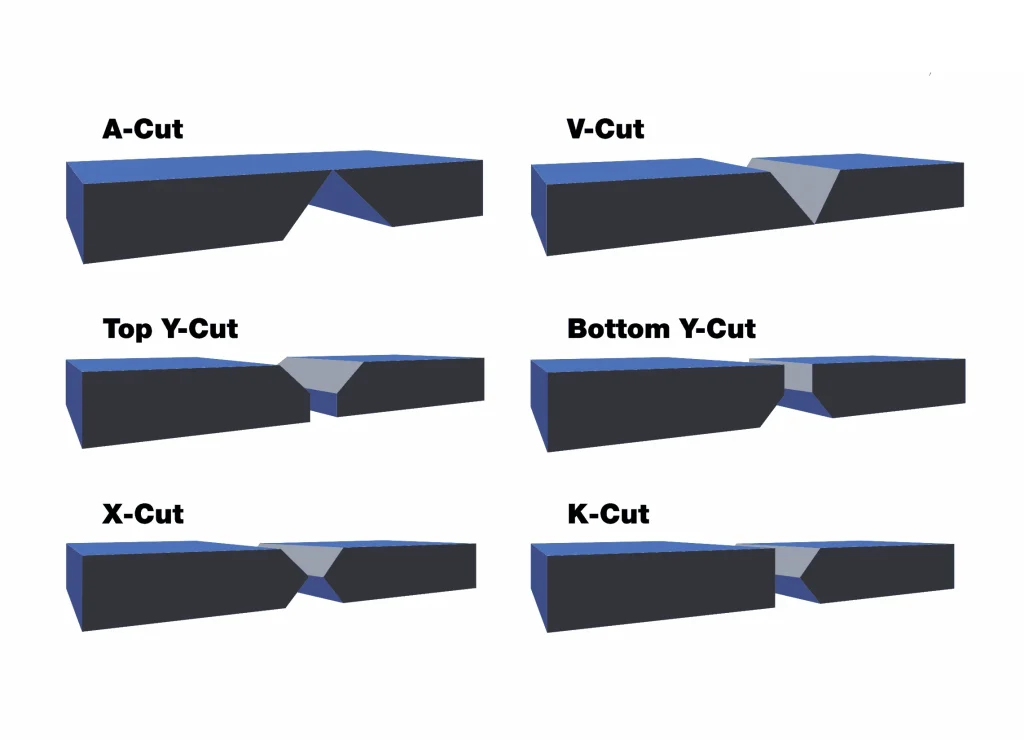

High-quality incisions for V, X, Y, and other groove shapes in a single pass.

-

Enhanced efficiency, reduced material loss, and improved weld quality.

Industry examples:

-

Shipbuilding: T-shaped low-alloy steel components are cut with precision, reducing weight while maintaining structural stability.

-

Construction machinery: High-strength steel structures are laser-cut to control welding heat, ensuring joint toughness and avoiding embrittlement.

Laser bevel cutting significantly improves processing efficiency, weld quality, and material utilization, making it the preferred choice over traditional flame or plasma methods in advanced manufacturing.