What is Laser Welding Nozzle?

The nozzle of a laser welding machine is an essential component located at the end of the welding head. Its primary functions are to control the flow and direction of auxiliary gas while protecting the focusing lens from contamination caused by welding splatter and debris. Below is a detailed explanation:

Functions of the Nozzle:

- Guiding Gas Flow:

The nozzle directs protective gases (e.g., argon, nitrogen) to the welding area, effectively shielding the weld pool, preventing oxidation, and improving weld quality. - Preventing Splatter Contamination:

The nozzle helps reduce contamination of the laser welding head and lens by blocking welding splatter, thereby extending the equipment’s lifespan. - Enhancing Welding Performance:

By optimizing gas flow and distribution, the nozzle maintains a clean welding area, improving the weld pool’s formation and quality. - Dissipating Heat:

Auxiliary gas passing through the nozzle carries away some of the heat, ensuring the stability of the welding head.

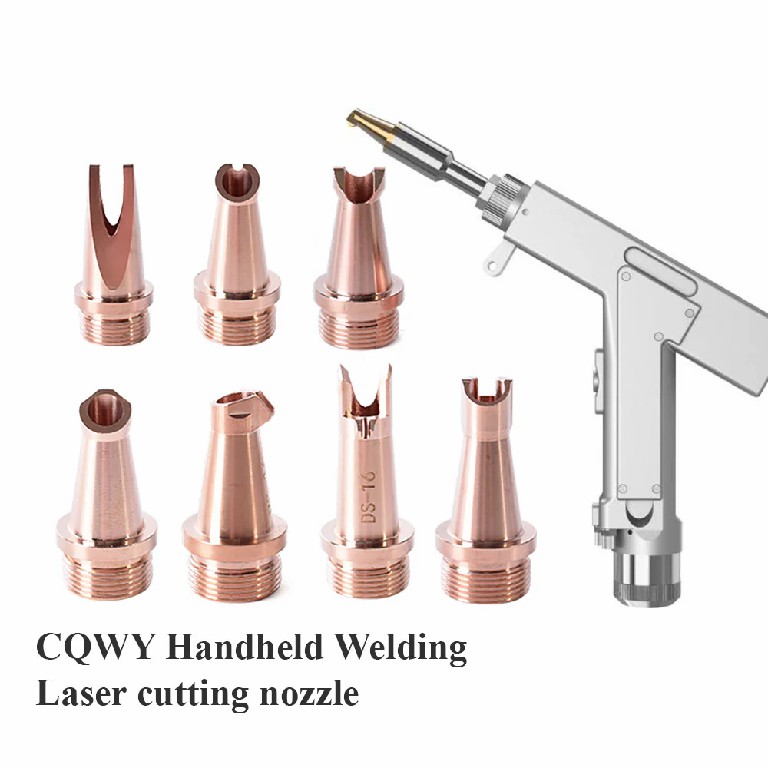

Common Types of Nozzles:

- Single-Hole Nozzle:

Delivers a concentrated gas flow, ideal for precision welding. - Double-Hole Nozzle:

Provides more uniform gas distribution, suitable for larger welding areas. - Circular Nozzle:

Features a surrounding gas flow design for better protection, ideal for high-demand welding processes.

Material Selection:

Nozzles are typically made of high-temperature and corrosion-resistant metals such as copper, brass, or stainless steel. Some nozzles are nickel-plated to enhance durability.

Cleaning and Maintenance of Welding Head

When using the welding head, a layer of black residue often adheres to the copper nozzle. This residue is caused by metal sparks splashing during heating and settling on the nozzle. Additionally, there may be dust particles in the air.

Cleaning Instructions:

- Clean the Nozzle:

After use, gently wipe the nozzle with a clean cloth to remove any residue. - Dust Removal:

Clean the welding head to remove accumulated dust. For better results, perform this cleaning in a relatively clean environment. - Inspect Protective Lens:

Pull out the drawer section of the welding head and check if the protective lens is clean. Clean it if necessary to ensure clear operation.

Maintenance Recommendations:

- Seal the Copper Nozzle:

When the welding head is not in use, seal the copper nozzle using tape or a rubber cap. This prevents dust from entering the lens area. - Protect the Fiber Connector:

If you remove the fiber connector, immediately cover the fiber input connector (QBH) hole with a dust cap. This prevents dust from entering the fiber connector and causing damage.