1. Prevention of Laser Condensation

Laser cutting machinery requires water cooling for both laser and optical components. Given the high temperature and humidity conditions, efforts to prevent condensation on the laser are crucial. Condensation could damage or disrupt the laser’s electrical/optical components, diminishing functionality.

The majority of laser and cutting head components utilize distinct water cooling. It is advisable to establish a low laser temperature and water temperature at around 22-26°C (depending on the machine power and high temperature alarm range of the laser). The cutting head and optical fiber water temperature is approximately 30°C (depending on temperature and humidity values).

During the summer, adhere strictly to the power on/off sequence. Incorrect laser on/off sequence can induce a sudden temperature disparity, leading to condensation. When the ambient temperature exceeds 25°, the recommended machine on/off sequence is as follows:

Startup sequence: Initiate the laser’s main power supply (air conditioner is activated), run the air conditioner for 30 minutes; then initiate the supporting chiller, await the water temperature to reach the preset temperature, and finally activate the laser light output.

Shutdown sequence: First deactivate the laser, then the chiller.

If condensation appears on the laser:

1. Shut down the laser immediately upon detection of condensation.

2. Clean the condensed water from the laser’s exterior surface and adjust the chiller temperature. Restart the laser once the condensation has been fully eliminated.

3. To cool and dehumidify the environment and achieve the required area, consider constructing an air-conditioned room.

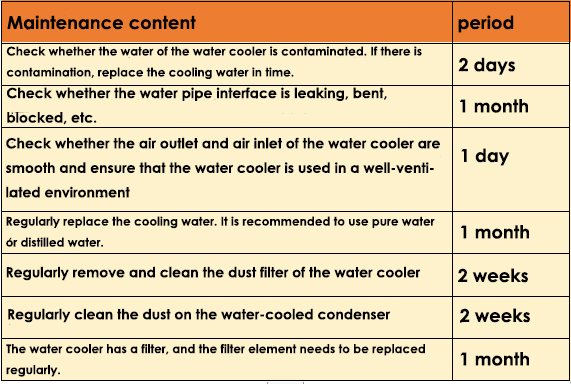

2. Daily maintenance content of water-Cooled machines

Prevention of laser condensation in high-temperature weather is directly linked to the water-cooler’s operational status. Hence, daily water-cooler maintenance is paramount. The specific cycle can be implemented as follows.

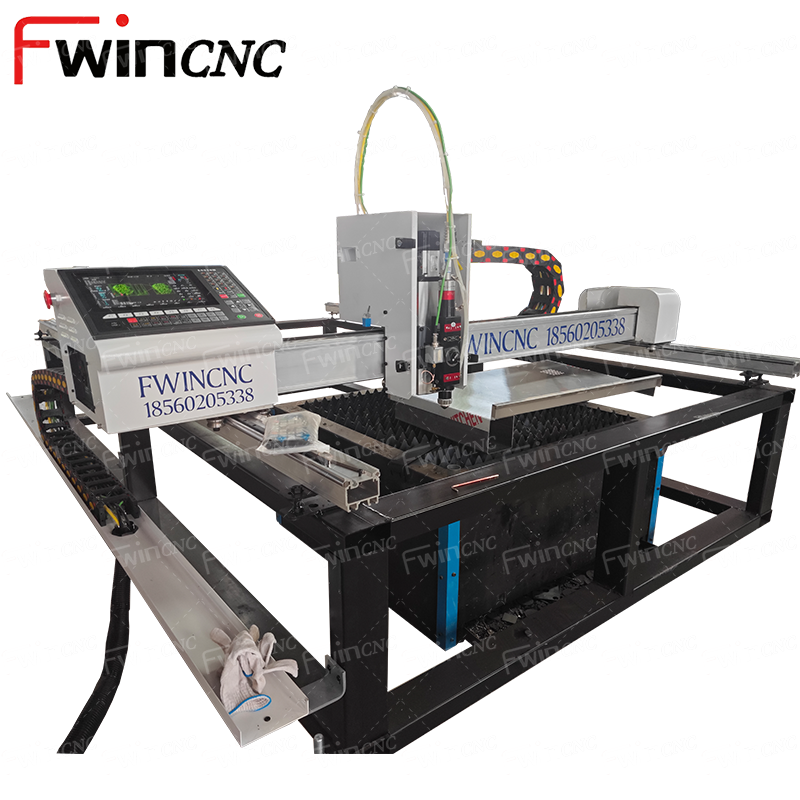

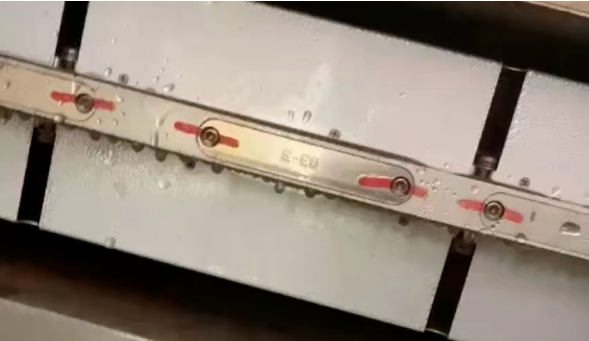

3. Guide Rails Lubrication and Maintenance

Each guide rail should be cleaned regularly to eliminate dust and debris, ensuring that the laser equipment operates normally. The rack should be frequently wiped and lubricated. The time should be adjusted to reduce it by 0.5-1 times compared to spring and autumn, and vigilant monitoring of oil quality is necessary.

·For machinery operating in high-temperature areas, increase the viscosity grade of the engine oil appropriately. Grease oil temperature is prone to fluctuations. Add oil as needed to ensure lubrication without debris.

·Examine meticulously the cutting table and laser cutting machine track’s straightness and machine’s verticality. Any abnormalities detected should be promptly rectified.

·The guide rails should be cleaned and lubricated frequently, and the motor should also be cleaned and lubricated regularly to maintain the machine in optimal condition. This ensures smoother movement and more precise cutting during operation, resulting in superior product quality.

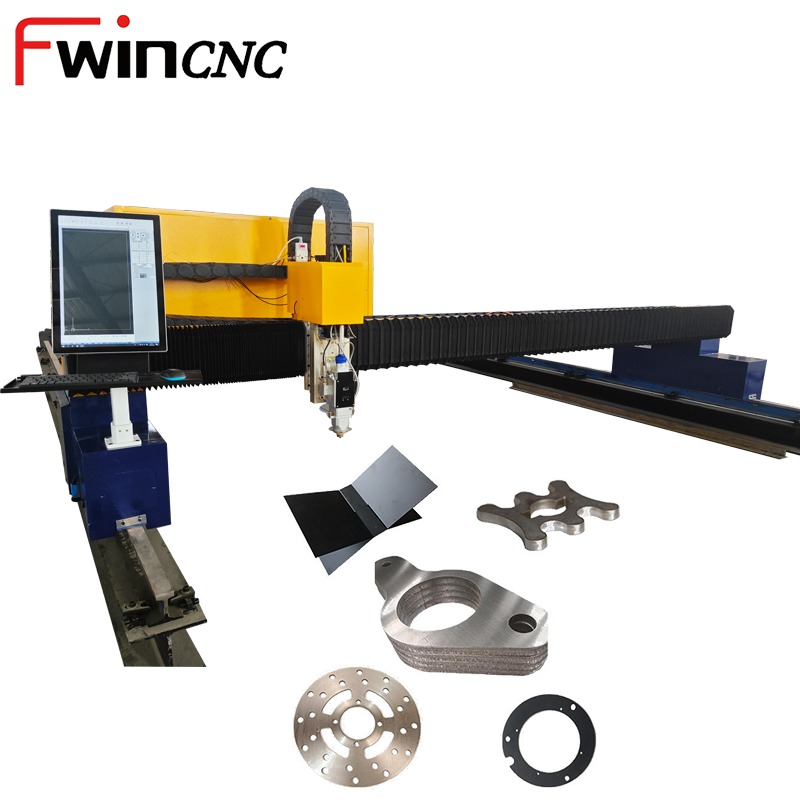

4. Machine Tool Cleaning and maintenance

Given the cutting site’s environment and excessive dust on the cutting material, the internal space of the cutting head cover of the machine must be routinely cleaned daily. High temperature weather can exacerbate the accumulation of metal dust+ oil+ flying sparks, potentially causing minor dust storms, leading to unnecessary losses.

As a large-scale integrated optical, mechanical and electrical equipment, the laser cutting machine undergoes rigorous installation and debugging. Its life begins after use. The best care for it is to standardize various protective and maintenance tasks during subsequent use and prevent issues before they arise.