3 sets of 5-axis CNC gantry bevel plasma cutting machines were shipped to Vietnam.

In the metal cutting industry, we all know that heavy plasma cutting machines and laser cutting machines are the current development direction. Many of our customers have chosen our machines from starting a business to upgrading their production workshops.

In November 2023, one of our Vietnamese customers ordered three of our FWINCNC 5-axis cnc gantry bevel plasma cutting machines.

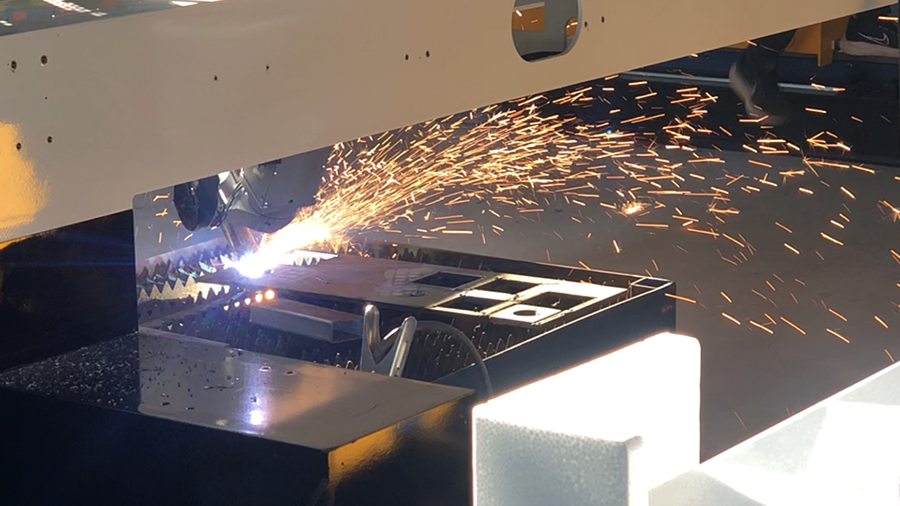

We did machine operation monitoring one day before delivery:

After confirming that all functions of the 5-axis cnc gantry bevel plasma cutting machines have passed the test, the machine is loaded onto a truck and its next stop is the port.

After receiving the machine, our Vietnamese customer said, “The machine is just as I expected. I can add it to my production workshop after I have tested it and found no problems.”

It can be seen that our 5-axis cnc gantry bevel plasma cutting machine has a good cutting effect, with less residue at the bevel and it is relatively smooth.

5-Axis CNC Gantry Bevel Plasma Cutting Machine Function:

- Excellent cutting versatility, suitable for mild steel, stainless steel and aluminum, etc.

- Up and down, left and right rotation 50° bevel cutting range to meet different slope requirements.

- Two types of cutting heads, plasma + flame cutting torch, flame cutting thickness can reach more than one meter.

- The x, y axis length of the machine can be customized according to your working area.

5-Axis CNC Gantry Bevel Plasma Cutting Machine Comparison:

1. Precision and Versatility:

Compared to light gantry plasma cutters, 5-axis cnc gantry bevel plasma cutting machines offer greater precision and versatility. The additional axes on a 5-axis machine enable it to perform complex cuts and bevels on three-dimensional workpieces with high precision, making it suitable for applications that require intricate detail.

Light-duty gantry plasma cutters typically have fewer axes and are better suited for simple two-dimensional cutting tasks that don’t require as much precision or complexity.

2. Cutting Capabilities:

5-axis cnc gantry bevel plasma cutting machines are capable of bevel cuts and complex shapes from all angles, offering a wider range of cutting options.

Light-duty gantry plasma cutters have more limited cutting capabilities and are typically used for simple two-dimensional cutting tasks on flat materials.

3. Efficiency and Productivity:

The multi-axis motion of a 5-axis CNC machine allows for continuous cutting without repositioning the workpiece, which increases efficiency and productivity.

Light-duty gantry plasma cutters may require manual adjustment or repositioning of the workpiece between cuts, which slows down the overall cutting process and reduces efficiency.

4. Cost and Size:

5-axis cnc gantry bevel plasma cutting machines are generally larger, more complex, and more expensive than lightweight gantry plasma cutters. They are designed for high-precision and advanced cutting applications, which may justify their higher cost for industries that require such capabilities.

Light-duty gantry plasma cutters are more compact and cost-effective, making them suitable for small workshops, hobbyists, or applications that do not require the advanced capabilities of 5-axis CNC machines.

5. Applications:

5-axis cnc gantry bevel plasma cutting machines are ideal for industries such as aerospace, automotive, metal fabrication, and other industries that require complex high-precision cutting capabilities.

Light-duty gantry plasma cutters are more commonly used in small workshops, DIY projects, or applications where simplicity and cost-effectiveness take precedence over advanced cutting capabilities.

5-Axis CNC Gantry Bevel Plasma Cutting Machine Advantage:

1. Increased flexibility: FWINCNC 5-axis cnc gantry bevel plasma cutting machines allow bevel cutting of three-dimensional workpieces, providing enhanced cutting flexibility. This flexibility is particularly beneficial for industries that require complex cutting contours and bevels.

2. Precision cutting: With additional axes, these machines can manipulate the cutting head in a more flexible manner, allowing for precision cutting along all axes. This precision is essential for industries such as aerospace, automotive, and metal manufacturing where precision is critical.

3. Increased production speed: The ability to perform multiple cuts and bevels in a single setup reduces production time, making these machines ideal for high-volume manufacturing environments.

4. Complex geometries: These machines can handle complex geometries and contours, allowing the production of complex parts and assemblies that are difficult or impossible to produce using traditional 2D or 3-axis cutting machines.

5. Improved material utilization: By optimizing cutting paths, these machines can reduce material waste, saving costs and improving sustainability.

In summary, the benefits of FWINCNC 5-axis cnc gantry bevel plasma cutting machines include enhanced flexibility, precise cutting, increased production speeds, the ability to handle complex geometries, and improved material utilization, features that make them valuable tools in modern manufacturing and machining processes.

How do I know if this 5-axis cnc gantry bevel plasma cutting machine is suitable for me?

Contact me now:

Contact infomation:

- Editor: Wendy

- Email: [email protected]

- Wechat/whatsapp:+86 18560786638

- Facebook: JINAN ALLWIN CNC MACHINERY CO.,LTD