5-axis gantry CNC plasma round tube

beveling cutting machine

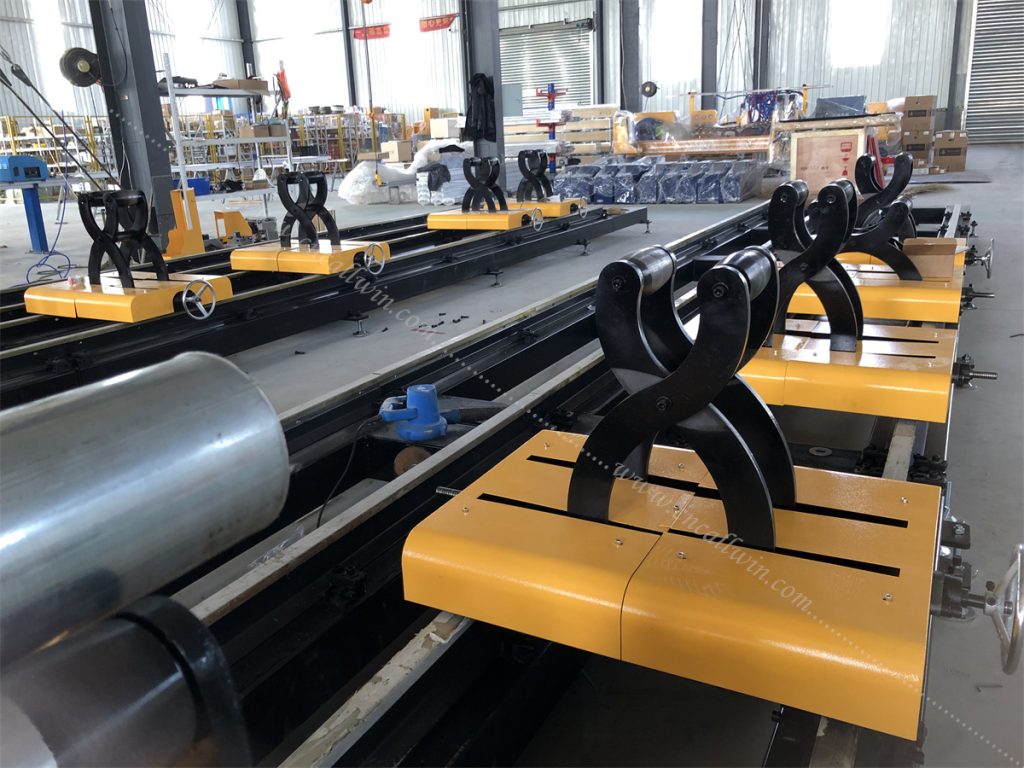

2 sets of 5-axis gantry CNC plasma round tube beveling cutting machines were shipped to Vietnam.

As we all know, the productivity of heavy duty special plasma machine is much higher than the Small plate and tube integrated machine plasma cutting machine, our Vietnamese customer’s demand is to cut large thickness round tube for a long time in large quantities, so he chose our 5-axis beveling heavy duty round tube plasma cutter after a period of time of consideration, the day before the delivery of the machine we did the running test, the above picture shows our 5-axis beveling heavy duty round tube plasma cutter The picture above shows our 5-axis beveled heavy duty round pipe plasma cutting machine cutting a 500mm diameter beveled round hole.

Our five-axis beveling heavy-duty round tube plasma cutting machine cuts round tubes with less residue and finer cuts.

After confirming that all functions of the machine have passed the test, the machine was loaded onto a truck, and its next stop is the port.

5-axis beveling heavy duty round pipe CNC gantry plasma cutting machine advantages:

- Precision Cutting: The 5-axis capability allows for intricate cuts and precise beveling on round pipes, ensuring high accuracy in complex geometries.

- Versatility: It can handle various pipe diameters and thicknesses, offering flexibility in production.

- Efficiency: The CNC automation reduces human error and increases production efficiency, especially for large volumes of pipe cutting.

- Beveling Capability: The machine can perform precise bevel cuts on round pipes at different angles, facilitating welding preparations and ensuring joint integrity.

- Complex Geometries: With the 5-axis movement, it can cut complex shapes and contours on pipes, which might be challenging with traditional methods.

- Cost-effectiveness: Despite initial setup costs, the machine’s efficiency and accuracy can lead to long-term cost savings in material waste and labor.

- Integration: It can integrate with CAD/CAM software, allowing for seamless design-to-cut processes and quick adaptation to design changes.

- High Production Capacity: Ideal for heavy-duty applications due to its robust construction and capability to handle large-scale pipe cutting projects.

- Quality Control: Ensures consistent quality in cuts and bevels, meeting stringent industry standards and specifications.

- Safety Features: Designed with safety protocols to minimize hazards associated with heavy-duty machinery operations.

These advantages make a 5-axis beveling heavy-duty round pipe CNC gantry plasma cutting machine suitable for industries requiring precision cutting of pipes with complex geometries and high-volume production needs.

Comparison between 5-axis beveling heavy duty round pipe CNC gantry plasma cutting machine and Small plate and tube integrated machine plasma cutting machine:

1. Application and Specialization:

5-axis Beveling Heavy Duty Round Pipe CNC Gantry Plasma Cutting Machine:

Application: Specifically designed for heavy-duty round pipe cutting applications.

Specialization: Focuses on precision cutting and complex beveling of round pipes, suitable for industries like shipbuilding, pipeline construction, and large structural components.

Small Plate and Tube Integrated Machine Plasma Cutting Machine:

Application: Versatile machine capable of cutting both small plates and tubes.

Specialization: Offers flexibility for various cutting tasks including flat plates and smaller diameter tubes, suitable for general fabrication needs in smaller workshops or facilities.

2. Capability:

5-axis Beveling Heavy Duty Round Pipe CNC Gantry Plasma Cutting Machine:

Capabilities: Handles a wide range of pipe diameters and thicknesses, providing flexibility in production.

Complexity: Can perform intricate cuts and beveling at various angles on round pipes, suitable for complex geometries and welding preparations.

Small Plate and Tube Integrated Machine Plasma Cutting Machine:

Capabilities: Capable of cutting small plates and tubes with moderate thicknesses.

Versatility: Provides flexibility for cutting various shapes and sizes of plates and tubes, but typically limited in diameter and thickness compared to the heavy-duty pipe machine.

3. Automation and Technology:

5-axis Beveling Heavy Duty Round Pipe CNC Gantry Plasma Cutting Machine:

Automation: Uses advanced CNC automation for high precision and efficiency.

Technology: Incorporates 5-axis movement for complex cuts, often integrated with CAD/CAM software for design-to-cut capabilities.

Small Plate and Tube Integrated Machine Plasma Cutting Machine:

Automation: Generally includes CNC capabilities for precise cutting of plates and tubes.

Technology: Designed for simpler operations and may not require as advanced software integration as the heavy-duty pipe machine.

4. Size and Footprint:

5-axis Beveling Heavy Duty Round Pipe CNC Gantry Plasma Cutting Machine:

Size: Larger and requires more space due to its heavy-duty construction and capability to handle large pipes.

Small Plate and Tube Integrated Machine Plasma Cutting Machine:

Size: Compact design suitable for smaller workshops or facilities with limited space.

5. Cost:

5-axis Beveling Heavy Duty Round Pipe CNC Gantry Plasma Cutting Machine:

Cost: Higher initial investment due to specialized capabilities and heavy-duty construction. However, can be cost-effective for large-scale pipe cutting projects.

Small Plate and Tube Integrated Machine Plasma Cutting Machine:

Cost: Generally more affordable compared to the heavy-duty machine, suitable for smaller budgets or businesses with varied cutting needs.

6. Speed and Production Efficiency:

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

5-axis Beveling Heavy Duty Round Pipe CNC Gantry Plasma Cutting Machine:

Speed: Efficient for large-scale projects, capable of handling high volumes of pipe cutting with precision.

Small Plate and Tube Integrated Machine Plasma Cutting Machine:

Speed: Generally faster for smaller-scale projects due to simpler setups and operations, but may not match the throughput of the heavy-duty machine for large pipes.

In conclusion, the choice between these machines depends on the specific requirements of the application. The 5-axis beveling heavy-duty round pipe CNC gantry plasma cutting machine excels in precision and complex pipe cutting tasks for heavy-duty industries. In contrast, the small plate and tube integrated machine plasma cutting machine offers versatility and affordability, making it suitable for smaller-scale operations with varied cutting needs across plates and smaller diameter tubes.

Contact me to get more free quotes and catalogs: